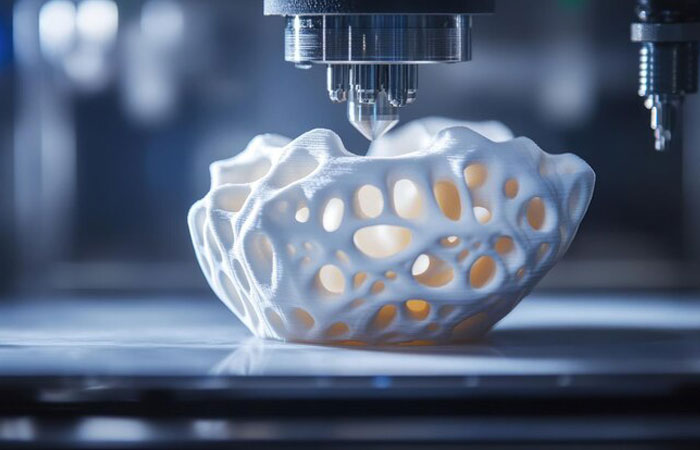

In the field of medical machining, additive manufacturing—specifically, 3D printing—has changed the game. In contrast to conventional subtractive manufacturing techniques, which entail cutting away material to form a component, 3D printing creates parts layer by layer, providing previously unheard-of levels of personalization and design freedom. Rapid prototyping and the development of patient-specific implants are just two examples of how this revolutionary technology is changing the manufacturing of medical components.

Transforming Prototypes to Implants

One of the most significant advantages of 3D printing in medical machining is its ability to rapidly produce prototypes. Traditionally, developing a prototype using conventional machining methods could take weeks or even months, involving multiple stages of design, tooling, and testing. With 3D printing, prototypes can be created in a matter of hours or days, allowing for faster iteration and refinement. This rapid prototyping capability accelerates the development process, enabling medical device manufacturers to bring new products to market more quickly.

Moreover, 3D printing is revolutionizing the production of implants, particularly those tailored to individual patients. Customization is critical in the medical field, where each patient’s anatomy is unique. Traditional machining methods often struggle to produce highly customized implants due to the complexity and precision required. In contrast, 3D printing excels in creating patient-specific implants, such as cranial plates, orthopedic implants, and dental prosthetics. These implants are designed directly from patient scans, ensuring a perfect fit and reducing the risk of complications.

Case Studies of Successful Implementations

Several case studies highlight the successful implementation of 3D printing in medical machining. For instance, a leading orthopedic company used 3D printing to create custom hip implants for patients with complex bone structures. The ability to produce implants that matched the exact geometry of the patient’s bones led to improved outcomes and faster recovery times.

Another notable example is the use of 3D printing in the production of cranial implants. A patient with a severe skull injury received a 3D-printed titanium implant that was designed to precisely fit the missing portion of their skull. The implant was lighter and more comfortable than traditional options, showcasing the potential of 3D printing to create better patient experiences.

Comparison with Traditional Machining Methods

While 3D printing offers numerous advantages, it also presents some challenges when compared to traditional machining methods. For instance, traditional machining is still superior in terms of producing parts with very high mechanical strength, as the layered structure of 3D-printed components can sometimes result in weaker material properties. Additionally, 3D printing can be slower and more expensive for producing large quantities of parts, making traditional machining more suitable for high-volume production.

Challenges and Future Prospects

Although 3D printing has great promise for medical machining, there are a number of obstacles to overcome. Material constraints continue to be a major obstacle, especially with regard to mechanical strength and biocompatibility. Furthermore, the safety and efficacy standards for 3D-printed medical devices are subject to strict changes in the regulatory landscape.

These issues are being addressed, though, as technology develops. The spectrum of uses for 3D printing in the medical industry is growing thanks to new materials and enhanced printing processes. With its unparalleled potential for personalization, speed, and accuracy, 3D printing is set to become an increasingly important component of medical machining in the future as the industry innovates.

image courtesy : Design by Freepik