Seco Nanojet Solid Carbide Reamers are revolutionizing chip control with an innovative through-coolant outlet, ensuring optimal chip evacuation and eliminating costly scrapped parts, jamming, and edge damage. This advancement enhances safety, part quality, and tool life, making it a game-changer in critical reaming operations.

Enhanced Coolant Flow for Superior Results

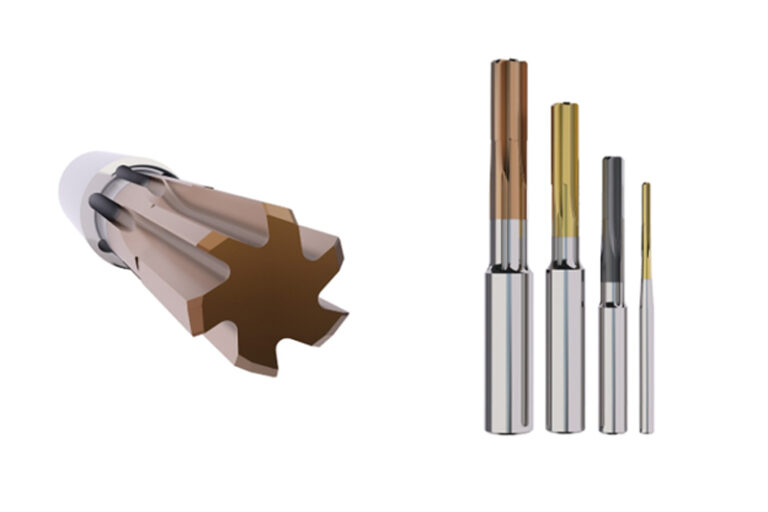

Seco Nanojet Solid Carbide Reamers feature through-coolant outlets that prevent chip jamming and improve stability in blind and through bores. The design directs lubrication precisely to the cutting zone, facilitating chip evacuation and prolonging tool life. With increased production stability, manufacturers rely on these reamers for consistent part quality.

Versatile Range for Varied Needs

Available in a versatile range of multi-flute options, Seco Nanojet Reamers offer eight grades and over 10 geometries, with custom sizes and tolerances. Compatible with any precision toolholder, they hold tight tolerances and produce fine surface finishes. Each reamer undergoes rigorous inspection for consistent performance.

Ensuring Predictable Precision

Industries such as general engineering, automotive, and aerospace rely on high-quality reamers to avoid costly scrap. According to Jean-Bernard Hantin, Product Manager at Seco, Nanojet Solid Carbide Reamers offer cost-efficient performance with quality and stability.

Customization Made Easy

Available in both stock and custom diameters, Seco Nanojet Reamers can be customized online with the MyDesign tool configurator, ensuring stability, reliability, and availability comparable to commodity products.