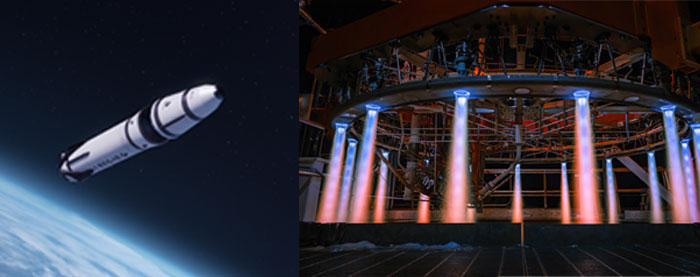

Stoke Space, a pioneering U.S. space launch company based in Kent, Washington, is on a mission to build the world’s most efficient fully reusable rockets. Central to their innovative approach is the additive manufacturing of copper thrust chambers, presenting a unique depowdering challenge. To tackle this challenge head-on, Stoke Space has turned to Solukon’s SPR® depowdering technology, recently acquiring an SFM-AT800-S system.

Discarded second stage that can reenter Earth’s atmosphere and land after deploying payloads in space, demand cutting-edge manufacturing solutions. Stoke’s in-house designed and additively manufactured thrust chambers feature complex inner structures with regenerative cooling channels and built-in manifolds, posing significant depowdering obstacles. Solukon’s SPR® technology, particularly exemplified by the SFM-AT800-S system, proves instrumental in overcoming these challenges.

The SFM-AT800-S stands out as Solukon’s flagship solution for demanding depowdering tasks, widely regarded as the go-to automated powder removal system in the additive manufacturing industry. With the capability to handle metal parts of substantial dimensions and weight, the SFM-AT800-S employs Solukon’s proprietary Smart Powder Recuperation (SPR®) technology. Through targeted vibration and unlimited 2-axis rotation within a controlled atmosphere, the system ensures the complete removal of unfused powder from metal laser melted parts.

Stoke’s choice of material, a special copper alloy renowned for its high conductivity and suitability for maximum reusability, introduces further complexities to the depowdering process. Copper powder’s propensity to adhere and form clumps within intricate channels necessitates specialized solutions. Stoke integrates a high-frequency knocker, provided as an add-on to the Solukon system, to dislodge trapped copper powder from internal cavities effectively. Additionally, an ultrasonic vibration system, directly linked to the component, enhances powder flow.

To address depowdering challenges arising from intricate geometries, Stoke leverages Solukon’s SPR-Pathfinder® software. This innovative tool analyzes CAD files of parts, generating optimized motion patterns for the Solukon system. By creating a digital twin of the part and calculating precise depowdering motions in advance, SPR-Pathfinder® streamlines the process and ensures efficient powder removal from complex structures.

Zach Sander, Head of Engine and Fluid Systems at Stoke Space, underscores Solukon’s pivotal role in their operations: “We chose Solukon for their industry-leading capability in automating depowdering of complex parts. Regeneratively cooled rocket engine thrust chambers are notoriously difficult to depowder, and we wanted to ensure we had a robust machine to reliably depowder these difficult copper components.”

Stoke Space’s partnership with Solukon exemplifies their commitment to innovation and efficiency, propelling them closer to realizing their vision of fully reusable, daily flying rockets.

Overall, the impact of implementing Solukon’s SPR® technology is multifaceted, contributing to increased efficiency, improved product quality, cost savings, and technological advancement for Stoke Space’s rocket manufacturing operations.