The metrology industry, dedicated to the science of measurement, is rapidly evolving with advancements in technology. As industries increasingly rely on precision and accuracy, the role of metrology has expanded beyond traditional applications. This article explores the key technology trends reshaping the metrology landscape, driving innovations across sectors like manufacturing, aerospace, and automotive.

Integration of Artificial Intelligence (AI) and Machine Learning

Artificial Intelligence (AI) and machine learning are revolutionizing metrology by enhancing data analysis and decision-making processes. AI algorithms can process vast amounts of measurement data quickly, identifying patterns and anomalies that would be difficult for human operators to discern. This integration facilitates real-time adjustments and predictive maintenance, improving the efficiency and reliability of measurement systems. AI-powered systems are also enabling more sophisticated calibration methods, ensuring higher accuracy and reducing downtime.

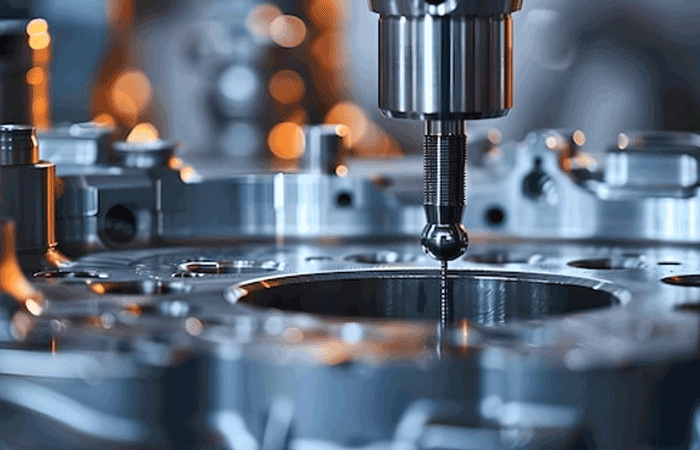

Advancements in 3D Scanning and Imaging Technologies

3D scanning and imaging technologies are becoming increasingly sophisticated, offering detailed and accurate representations of objects. Laser scanning, structured light scanning, and optical metrology are leading advancements in this area. These technologies provide high-resolution, three-dimensional data, which is essential for quality control, reverse engineering, and design verification. The ability to capture intricate details and complex geometries in a non-destructive manner is transforming industries that require precise measurements of components and assemblies.

Rise of Internet of Things (IoT) and Connected Metrology Systems

The Internet of Things (IoT) is bringing connectivity to metrology systems, enabling them to communicate and share data seamlessly. IoT-enabled measurement devices can integrate with other systems and platforms, creating a more interconnected and automated measurement environment. This connectivity facilitates real-time monitoring and remote diagnostics, allowing for more proactive maintenance and faster response to measurement issues. The rise of connected metrology systems also supports Industry 4.0 initiatives, promoting smarter manufacturing processes and enhanced data analytics.

Miniaturization and Precision in Measurement Tools

Miniaturization is a significant trend in metrology, driven by the need for precision in increasingly compact and complex components. Advances in micro-metrology tools are enabling measurements at the nanometer scale, which is critical for industries such as semiconductor manufacturing and microelectronics. Enhanced precision tools, such as micro-coordinate measuring machines (CMMs) and atomic force microscopes (AFMs), are providing higher resolution and accuracy, supporting the development of cutting-edge technologies.

Adoption of Portable and Handheld Metrology Devices

Portable and handheld metrology devices are gaining popularity due to their versatility and ease of use. Technologies such as portable CMMs, handheld laser scanners, and mobile measurement systems offer flexibility and convenience, allowing for measurements in various environments, including remote or difficult-to-access locations. These devices are enhancing field inspections, on-site quality control, and real-time data collection, making them invaluable tools for industries with dynamic measurement needs.

Enhanced Software Solutions and Data Analytics

The evolution of metrology software is significantly improving the capabilities of measurement systems. Advanced software solutions provide comprehensive analysis, visualization, and reporting tools, enabling users to interpret complex measurement data more effectively. Features such as advanced statistical analysis, simulation, and integration with CAD systems are enhancing the ability to perform in-depth evaluations and ensure product quality.

Focus on Sustainability and Green Technologies

Sustainability is becoming an important consideration in the development and application of metrology technologies. Efforts are being made to reduce the environmental impact of measurement processes, including the use of eco-friendly materials and energy-efficient systems. Green technologies are being incorporated into metrology equipment, supporting the industry’s commitment to environmental responsibility.

The metrology industry is experiencing significant technological advancements that are transforming measurement practices. From AI and machine learning to IoT connectivity and miniaturization, these trends are driving innovation and improving the accuracy, efficiency, and sustainability of measurement systems. As industries continue to evolve, metrology will play a crucial role in ensuring the precision and reliability of the technologies and products that shape our world.