New development in a class of its own

JUNKER opens up far-reaching options for the future with the new development of Platform 3. Celebrate the world premiere from May 14 to 17 at GrindingHub 2024.

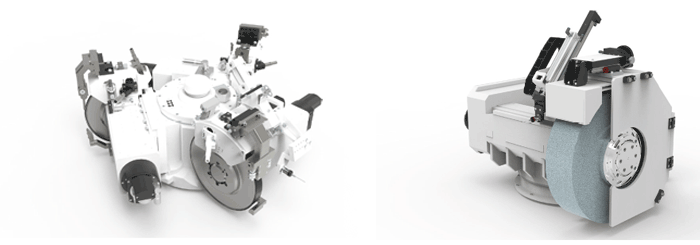

JUNKER‘s grinding technologies are constantly being further developed and presented with the challenges of the market. With ever more productive grinding concepts, JUNKER offers the perfect solution for continually increasing demands on effi ciency and precision. Platform 3 was designed with this in mind right from the development stage. Experience our new developments live at our booth B50 in hall 10. We will present the JUMAT 3S for high-speed grinding with CBN and the JUNICOR 3L for corundum applications.

JUMAT 3S – New answers for fl exible manufacturing processes

Effi ciency, fl exibility, economy – the JUMAT cylindrical grinding machine leaves demand nothing. During GrindingHub 2024, you can experience the grinding of high-speed shafts yourself. We use CBN wheels to grind diameters, shoulders, and ends, while the peel-grinding technology comes into play for the diameters. Due to the different grinding spindles, grinding grooves, and bearing seats that are twist-free, using a traditional plunge-cut process is also possible.

The main goals of the new development are to increase fl exibility and cost-effectiveness by optimizing the modular system. The advantages of the modular system include a uniform basis for all Platform 3 machine models, which reduces throughput times and allows customers to benefit from shorter delivery times.

Joachim Himmelsbach (CTO of the JUNKER Group)

JUNICOR 3L – Precision grinding with corundum

The JUNICOR corundum grinding machine, an outstanding addition to the JUNKER Group portfolio, impresses with its precision and variable confi guration options. Our new JUNICOR covers all conventional corundum grinding requirements. It is ideal for grinding workpieces of all sizes, offers maximum fl exibility, and achieves outstanding grinding results. The JUNICOR will be presented for the fi rst time at GrindingHub

2024, grinding diameters and shoulders on Turbocharger shafts using angular plunge-cut grinding.

Filtration systems as the perfect complement

LTA fi ltration systems guarantee effi cient and sustainably cleaned air by extracting cooling lubricant mist in the metalproducing industry. Dust fi lters, pipework, fi re protection systems, and central extraction systems complete the allaround service provided by the specialist for clean air.