Automotive repairs involve rigorously checking a variety of mechanical and electrical systems to diagnose the problem. Getting to just the first step of deducing a problem can be a troublesome, time-consuming process, especially in an industry where clients need their vehicles back as soon as possible. Traditional methods for troubleshooting include manually testing components for odd vibrations or noises, fault detecting with multimeters, and running diagnostic software that still might not pinpoint the exact issue. In both mechanical and electrical problems, resistance from components generates heat and makes issues light up under thermal imaging—making thermal cameras the perfect tool for quickly diagnosing auto issues and speeding up initial inspections.

Mechanical Issues

Operating mechanical parts will always create some level of heat from friction. When mechanical issues come up, they tend to create higher than normal levels of heat from issues like failing seals or parts seizing up. Technicians can take advantage of this by looking for out of place hot spots through a thermal imaging camera while diagnosing an issue.

One example is when pistons in brake calipers occasionally won’t return properly due to worn seals, which can then lead the rotor warping, vibration, and uneven wear and performance. Calipers inside a vehicle’s brakes are typically inspected visually by mechanics, but this process can be sped up with thermal imaging. If a client is reporting potential brake issues, an auto technician using a thermal imaging camera can quickly identify a dragging caliper by comparing two matching rotors to determine if one is a higher temperature than the other. The technician can find the problem caliper quickly and begin deeper analysis.

Electrical Issues

Diagnosing electrical issues has been a common application for thermal imaging in a variety of fields and the auto industry is no different. Thermal imaging is a great, non-contact method for locating electrical problems by identifying hotspots caused by high resistance, loose connections, or faulty components in the wiring harness, fuses, or relays.

When electric systems are operating with power running through them, there should be a standard and consistent amount of heat emitted from the components and connections. Electrical malfunctions will typically cause electric systems to generate temperatures outside of that standard. When diagnosing electrical issues, users should check connections and components displaying unusually high or low temperatures that shouldn’t occur during standard operation. Higher than average temperatures are usually a sign of a poor connection creating high resistance or potentially a ventilation problem. Lower than average temperatures are usually a sign that power is not being delivered properly or that a component needs replacement. Having a solid understanding of your electric systems typically operating temperature will allow you to perform efficient thermal inspections.

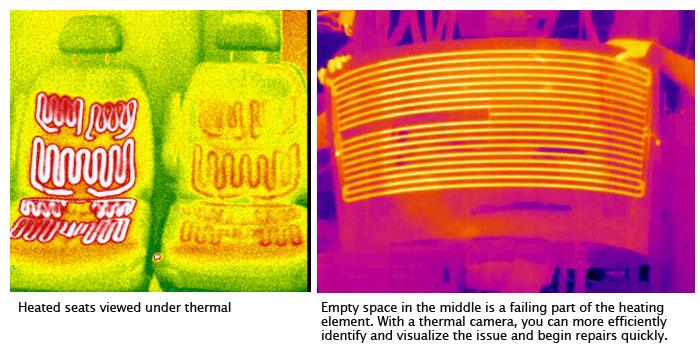

Diagnosing heating element issues is made immensely more efficient with a thermal imager. Instead of manually checking a long an area with a spot thermometer, you can quickly scan multiple areas at once with a quick pan of a thermal camera. Heating elements are highly defined under thermal imaging through car seats and steering wheels and can be validated almost instantly. If any part of the element isn’t operating correctly, the malfunctioning section will appear much colder than the rest and can be quickly identified for repair or replacement.

Thermal imaging can also be used to validate that AC and heating are working properly. A quick thermal scan inside the vehicle and around vents will show you whether your vehicle is reaching the intended temperature. Scans outside the vehicle can be helpful as well as any drafts will appear as hot or cold spots along the body, letting a technician know that door and window seals may need to be replaced.

Thermal cameras can additionally be used to monitor the temperatures of batteries and other high-voltage components in hybrid and electric vehicles. The battery packs used to power electric vehicles are large modules built using several smaller batteries. These modules are installed into a rigid frame and connected to create a larger, finished battery pack. Ensuring these modules are connected properly is immensely important as improper connections between modules can result in high resistance, leading to a loss of power or even a battery fire. A thermal imaging camera allows technicians to quickly scan an electric vehicles battery and confirm there are no high resistance connections.

Flir Solutions

Teledyne FLIR manufactures and designs thermal imaging cameras with a wide variety of professionals in mind, including auto technicians. Our cameras are designed to not only reveal thermal information, but also have intuitive, beginner friendly operation so that any technician can pick up a camera and begin diagnosing problems with little to no training in thermal camera operation. Below are three of our picks for cameras that provide ease-of-use and mobility for auto professionals.

The Flir ONE® Edge

The FLIR ONE Edge Series is FLIR’s premiere mobile thermal camera that’s compatible with both iOS and Android smart devices. The camera wirelessly connects to your smart device allowing a flexible range of motion and great views on components in hard-to-reach areas. Powered with FLIR MSX®, the on-board visible camera will add extra details to thermal images to ensure no detail is missed and maximum clarity is achieved. Compatibility with both iOS and Android means that any employee can connect the camera to their own smart device, which allows every technician to operate with the device they’re most comfortable with. The FLIR ONE Edge also features a 2.5-hour battery life with fast charging capabilities, an IP54 rating and is two-meter (6.6 ft) drop-tested. This means you don’t need to worry about your battery dying or your device being damaged should you drop it while inspecting. This wireless camera has a wide variety of mobile applications as well that can guide you through thermal inspections and get its user up to speed on thermal camera operation. The FLIR ONE Edge is the perfect camera for those looking for an affordable intro to thermal imaging.

The Flir TG275

The lightweight, handheld FLIR TG275 thermal imaging camera is designed to help you diagnose problems and discover potential failure points. The TG275 is an all-in-one diagnostics tool with a spot temperature gun and thermal imager, enhanced by FLIR’s patented Multi-spectral Dynamic Imaging (MSX). A laser-projected bullseye target aids in pinpointing areas of concern, while the bright 2.4-inch LCD color display and wide field-of-view provide a comprehensive view for faster, easier diagnostics.

The Flir EX PRO-Series

The FLIR Ex Pro-Series is the camera line for auto professionals who want to have the full capability of thermal imaging in their hands. These pistol grip cameras deliver up to 320 × 240 thermal resolution images with vibrant imagery for highlighting minute temperature differences. Thermal images are also enhanced thanks to FLIR MSX® which adds more detail and contrast to your images, making identifying areas easier. The Ex Pro- Series comes with 1-touch level/span to make calibrating your thermal view as easy as touching the screen to find the best image contrast. And its intuitive touchscreen allows users to add notes and organize files directly from the camera.

Flir Software

FLIR provides an array of software to allow professionals to get even more out of their images after they’ve been taken. FLIR Thermal Studio is our thermal analysis software that allows users to view and edit their images on their computer. This software is not only great for having a larger view of your images, but fine tuning your images after inspections can make it easier to convey problems to the client.

Both the FLIR ONE Edge and the FLIR Ex Pro-Series are compatible with FLIR Ignite™, FLIR’s secure cloud storage that lets users upload their images directly from the camera. FLIR Ignite™ also allows users to edit images directly from a desktop or mobile browser for easy annotation, analysis, and organization.

Conclusion

Thermal imaging is a powerful tool for auto diagnostics and is easier than ever to get into. Get through the diagnosis phase faster and get your clients back behind the wheel sooner by adopting thermal into your workflow for both mechanical and electrical issues. Whether you’re looking to quickly leverage thermography with a simple tool like the FLIR ONE Edge or FLIR TG Series, or you’re looking to perform more in-depth diagnostics with the Ex Pro-Series, FLIR has you covered in both hardware and software.

Visit: https://www.flir.com/