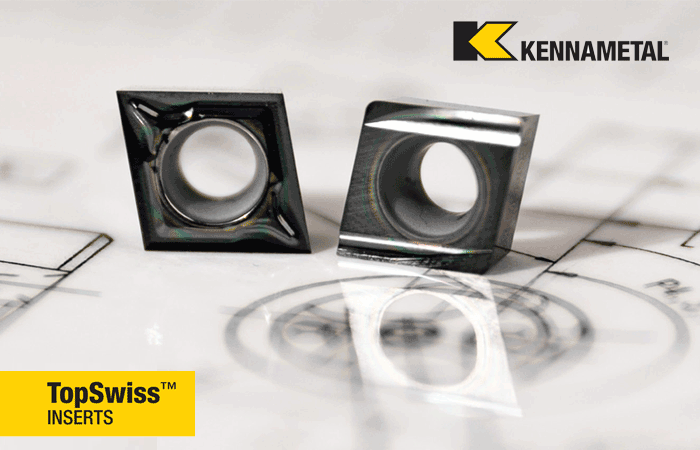

TopSwiss small parts machining inserts enhance Kennametal’s turning portfolio with better solutions for aerospace, general engineering, medical and transportation customers facing challenges with achieving superior chip evacuation and surface finish in low feed, high depth-of-cut applications.

These inserts are an ideal choice for medium, light as well as fine finishing operations across materials like steels, stainless steels, high-temp alloys and non-ferrous.

TopSwiss inserts come equipped with several standout features, including: 4 new carbide grades, 1 new cermet grade and 7 new geometries; straight and curved cutting edges for stable cuts and smooth chip flow in low feed, high DOC applications; polished finishing geometries for increased welding resistance and improved surface finishing; medium and finishing wiper geometries for increased feed rates and superior surface quality, and several geometries with high chip breaker walls and large pockets for better chip evacuation.

“We’re continually building on our turning portfolio with next level solutions that meet the application needs of our customers globally.

TopSwiss Turning Inserts are a testament to this continued commitment to innovation and to delivering customers high performance products. These inserts are our latest solution for shops running low feed, high depth-of-cut applications and looking to achieve better chip evacuation and surface finishing,” said Scott Etling, Vice President of Global Product Management.

We’re continually building on our turning portfolio with next level solutions that meet the application needs of our customers globally. TopSwiss Turning Inserts are a testament to this continued commitment to innovation and to delivering customers high performance products. These inserts are our latest solution for shops running low feed, high depth-of-cut applications and looking to achieve better chip evacuation and surface finishing.