Modern milling, as a metal cutting method, originated in the late 18th century and quickly became one of the primary machining technologies. Today, it is hard to imagine any machine shop without milling machines on the shop floor. Milling is an essential process in manufacturing.

Milling, is an integral part of machining technology, driven by the increasing demands of manufacturing. However, there are specific aspects that uniquely impact the advancement of milling.

Today, we are witnessing significant changes in manufacturing that will have profound consequences on the development of directions of milling. These changes are driven by various factors, such as the increasing accuracy of metal shaping through precision investment cutting and precision forging, the widespread adoption of 3D printing, the growing usage of new composite and sintered materials, the need to enhance productivity in machining hard-to-cut superalloys and titanium grades, and the strong focus on electric and hybrid cars in the automotive industry, contributing to these changes. In addition, advancements in multi-axis machine tools have opened up new possibilities for precise machining of complex parts and have enabled the implementation of new cutting strategies to improve productivity. In modern technological processes, there is a tendency to significantly reduce the amount of machining stock intended for milling operations, while simultaneously increasing the requirements for surface finish and accuracy.

Therefore, the advancement in milling is driven by the need for higher productivity, more precision, and sustainability in milling operations. Consequently, the main developments in milling can be characterized as follows:

- Fast metal removal focuses on boosting the metal removal rate (MRR) to achieve higher productivity by significantly increasing cutting speed or feed per tooth. This is achieved through techniques such as high speed milling (HSM) and, in rough operations, high feed milling (HFM).

- Precision milling provides higher accuracy in milling operations.

- Multi-axis milling is characterized by the utilization of multi-axis machining centers to enable complex milling operations.

- Adaptive milling aims to develop intelligent milling systems that can adapt to changing conditions during the machining process.

- Sustainable milling strives to reduce the environmental impact of milling operations. It involves the development of eco-friendly cutting fluids, recycling and reusing of materials, and the use of energy-efficient machine tools and milling cutters.

The success in these areas relies on the synergy of several key components, namely machine tools, cutting tools, and computer-aided engineering (CAE) systems. High-speed milling, for instance, necessitates machine tool technologies capable of handling exceptionally high rotational velocities, as well as advanced cutting materials and coatings for milling tools. Simultaneously, enhancing the precision of milling operations requires not only milling cutters with tighter tolerances but also improved control systems and linear motor drives. In the case of multi-axis milling, the breakthrough lies in the addition of more effectively controlled axes of movement, along with the application of appropriate cutting geometries for milling tools. Adaptive milling, on the other hand, incorporates innovations such as the use of state-of-the-art monitoring systems, high-sensitive sensors, and efficient algorithms to optimize cutting data and tool paths in real-time. Moreover, sustainability advancements require energy-efficient milling strategies that employ suitable machine tools, cutting tools, and eco-friendly coolant techniques.

Indexable milling reflects the ways of advancement that feature exchangeable cutting inserts in machining operations.

- Advanced insert materials is an ongoing process to improve the cutting materials for indexable milling inserts including the development of advanced carbide grades, ceramics, and ultra hard cutting materials.

- Coating technologies with continuous R&D focuses on new coatings to improve wear and heat resistance while enhancing lubricity.

- Progressive cutting geometry optimizes cutting geometry and chip forming topology of inserts to improve cutting action, diminish cutting forces, and chip flow in milling operations.

- The effective utilization of cutting material incorporates intelligent insert design to provide maximum indexable cutting edges without reducing cutting capabilities.

In addition, the distinct course on smart manufacturing requires the integration of digitization into milling operations and milling tools. Referring to milling tools, digital twins and appropriate software applications have already become the “must” features of a comprehensive tool range.

How can cutting tool producers rise to the challenge? Which milling tool solutions will provide the right answer to the emerging trends? Is the field of cutting tool manufacturing, often considered conservative in metalworking, capable of delivering a timely response to current demands? The recent advancements from ISCAR provides greater insights to these subjects.

High speed trochoidal milling involves following a curvilinear tool path to maintain a constant load on the cutting edge, thereby eliminating sudden spikes in load during material entry. This strategy is highly efficient for milling deep slots, pockets, and cavities, especially in cases of low machining stability. Additionally, trochoidal milling has shown excellent results when working with challenging materials such as hard steels or high-temperature superalloys (HTSA).

The CHATTERFREE EC-E7/H7-CF is a new family of multi-flute solid carbide endmills, which are intended specially for trochoidal milling techniques. The geometrical design of the family includes different helix angles and variable angular pitches to improve dynamic behavior. These endmills are available in a range of cutting length-to-diameter ratios (Fig. 1).

With the help of modern machine tools, highly productive milling of aluminum alloys can be achieved at extremely high spindle speeds, reaching up to 33000 rpm. To meet this machining challenge, ISCAR has developed 90° indexable milling cutters that accommodate large-size inserts for a depth of cut of up to 22 mm (.870″) (Fig. 2). The cutters have been specifically designed to eliminate insert radial displacement, which may occur due to the high centrifugal forces generated during very high rotational speeds.

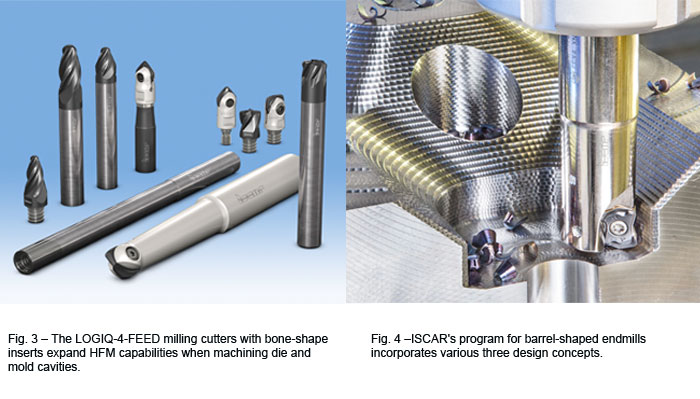

High feed milling (HFM) has become a widely adopted method for efficient rough machining of both complex and flat surfaces. ISCAR offers a comprehensive range of HFM products to meet the demands of various industrial applications. Recently, the range has been expanded with new additions. The LOGIQ-4-FEED family of HFM tools, featuring specific bone-shaped inserts (Fig. 3), now includes tools with larger inserts. These new products significantly broaden the application range, particularly in high feed milling of large-sized cavities in the Die and Mold industry. Another addition is NEOFEED, a family of HFM tools with double-sided square inserts, providing 8 cutting edges for improved cost-effectiveness.

Advancements in multi-axis machine tools and CAD/CAM systems have given rise to precise milling of complex shapes with minimal machining stock, using segment or barrel-shaped endmills. ISCAR’s program for these endmills encompasses three design concepts: a solid carbide design, an exchangeable MULTI-MASTER head, and a one-insert approach (Fig. 4).

When milling high-temperature superalloys (HTSA), cutting ceramics offer the ability to substantially increase cutting speeds. In fact, cutting speeds can reach up to 1000 m/min (3300 sfm). ISCAR’s latest ceramic tools include ceramic solid endmills and indexable milling cutters with double-sided round ceramic inserts. The double-sided design is aimed at maximizing the utilization of ceramic material grades, such as “black” ceramic, whisker-reinforced ceramic, and SiAlON (a type of silicon-nitride-based ceramic).

These selected examples serve as good illustrations of the main directions of advancement in milling tools. As new demands arise, new solutions are required, and these new challenges will fuel the search for innovative tool designs

Visit: https://www.iscar.com/