SCHUNK is the world’s No. 1 for gripping systems and clamping technology – from the smallest parallel gripper to the largest chuck jaw program.

SCHUNK is the world’s No. 1 for gripping systems and clamping technology – from the smallest parallel gripper to the largest chuck jaw program.

To boost efficiency, SCHUNK customers have bought more than 2,000,000 precision toolholders, 1,000,000 SCHUNK grippers, and 100,000 lathe chucks and stationary work holding systems so far.

Our customers profit from the expert knowledge, the experience, and the team spirit of about 3,500 employees in our innovative family-owned company.

SCHUNK Intec India Pvt Ltd, a 100% subsidiary of SCHUNK GmbH & Co. KG, established in 2001, has successfully supported the Indian manufacturing Industry in optimizing and perfecting the manufacturing process. SCHUNK Intec India Pvt Ltd has a strong product stock to support the industry in time; its design capabilities ensure quick and special solutions where necessary and the service facility assures German quality maintenance of products. The sales network is present PAN India in all major and minor industrially populated regions.

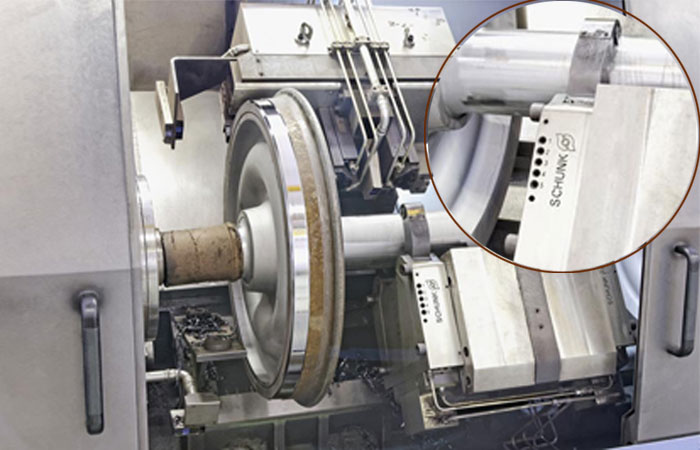

The solution from SCHUNK – Efficient wheel set maintenance with high flexibility

Workpiece:

40 different types of railway wagon wheel sets

Task:

Flexible machining of different types of wheel sets without the need for any major conversions.

Solution

The wheel sets are placed on two ZENTRICO THL plus steady rests, are automatically centered, and axially clamped between a hydraulically actuated center from SCHUNK and the tailstock. On the spindle side, the wheel set is transported using different adapters adjusted to the corresponding shaft types, which the customer has designed and manufactured itself in close cooperation with SCHUNK. Due to optimized lever kinematics, central lubrication, integrated roller rinsing, and dirt guard, the steady rests achieve maximum clamping forces for each roller, as well as constantly excellent centering and repeat accuracies. The hydraulic center developed by SCHUNK is impressive with its solid design and compact dimensions.

Customer benefits

With the help of SCHUNK products, the customer has developed a particularly economical machine for efficiently refurbishing railway wagon wheel sets, enabling efficient wheel set machining even at smaller locations.