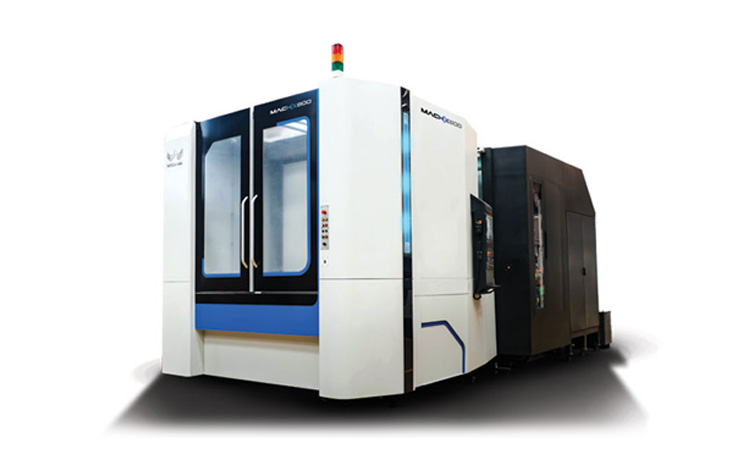

WIDMA® Machining Solutions, part of Kennametal India Limited, has launched the MacHX800 Horizontal Machining Center (HMC), a powerful new tool designed to meet the demands of large-part machining across industries such as aerospace, construction, commercial vehicles, and general engineering. Engineered with Industry 4.0 compatibility and next-gen technology, the MacHX800 is optimized for handling complex, large components with high precision and productivity, even in tough operating conditions.

The MacHX800 is tailored for both complex and high-volume operations, incorporating features that enhance usability and performance:

- Exceptional Precision: Engineered for accuracy, the MacHX800 minimizes per-component costs and maximizes productivity.

- User-Friendly Operation: With ergonomic features that simplify loading and unloading of large components, operators benefit from both ease of use and safety.

- Industry 4.0 Ready: Fully compatible with Industry 4.0 environments, enabling seamless integration and data-driven insights for enhanced efficiency.

This innovative HMC offers adaptable options, including customizable spindles, pallets, and tool magazine choices, allowing manufacturers to tailor the MacHX800 to specific machining requirements and reach higher productivity goals.

The MacHX800 demonstrates WIDMA’s commitment to partnering with clients to overcome productivity challenges, offering a robust, future-ready solution for complex machining needs.

For more information, Website: www.kennametal.com