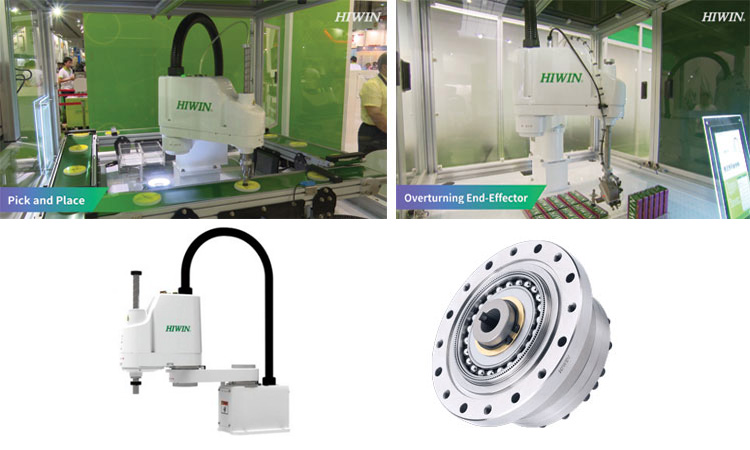

HIWIN’s SCARA robots are advancing industrial automation with unmatched precision and adaptability. These versatile robots integrate seamlessly with linear modules, vision systems, and end effectors, making them valuable for diverse operations—ranging from assembly and material handling to packaging and inspection. With a cycle time of just 0.46 seconds and repeatability within ±0.01 mm, they enhance production efficiency across fields while maintaining consistent quality. The controller’s compact design, reduced by 55%, along with optional protection versions and CE certification, makes SCARA robots an optimal choice for many industrial applications.

Enhancing HIWIN SCARA robots is the DATORKER® Strain Wave Gear, an innovative component designed for high precision and efficiency. Unlike traditional gears, DATORKER® uses elastic deformation to eliminate backlash, ensuring ultra-smooth rotational motion with high positioning accuracy. This feature makes it ideal for applications demanding high torque and precision, such as robotic arms and semiconductor equipment.

The DATORKER® Strain Wave Gear stands out for its compactness and energy efficiency, thanks to its thin-walled metal flexspline design that maximizes torque while minimizing size. This contributes to the miniaturization of automation systems, a critical advantage for industries seeking to conserve space and reduce weight without sacrificing performance. It also supports sustainable manufacturing by optimizing energy use, aligning with green technology trends.

HIWIN’s SCARA robots, enhanced with DATORKER® Strain Wave Gears, deliver a robust solution for precise automation across sectors. With their flexibility, high-speed operation, and compact design, they are well-suited for industries looking to improve operational efficiency while meeting modern demands for sustainable production.

For further details, visit www.hiwin.tw