“It all started in a garage…” is the beginning of many, well-known origin stories for successful entrepreneurs and companies. It’s also true for SendCutSend CEO Jim Belosic who uncovered his passion for design and manufacturing in a garage—and a huge business opportunity that came along with it.

Belosic had always tinkered with and fabricated parts for boats and vehicles over the years. While running a software company, he realized how the actual making of a physical object was important to him. As his projects in the garage became more complex, he realized he couldn’t make parts at the quality level he wanted with the hobby-level tools he had on hand.

“I started exploring local resources and machine shops, and I found no one wanted to do one part for someone in his garage,” Belosic says. “They wanted to do a thousand parts, or it was a very high price. And all I really wanted was something like a custom dashboard for a car.”

Then the light-bulb moment happened. Accessible, affordable, small-batch manufacturing was a major hurdle for many. Belosic realized there was a business opportunity to manufacture that one part or product for one person. Little did he know at the time that larger customers wanting larger quantities might also have a similar need. SendCutSend was born soon after in 2018 with the purchase of its first machines, including a high-end AMADA fiber laser cutter.

Since then, it’s grown to produce over 1500 tons of products annually, 200 employees, a 70,000 square-foot headquarters and manufacturing site in Reno, Nevada, a 40,000 square-foot site in Paris, Kentucky, and a third location soon to be announced.

Building a manufacturing business with a few clicks

The business started out serving people who didn’t have access to a high-tech manufacturer, such as someone building a one-off telescope or a kit aircraft or making a replacement part for a classic car. Part of the business appeal for these customers was—and continues to be—the simplicity and affordability SendCutSend offers.

“We’ve worked really hard to make sure you can get something like a car part you can’t find anywhere else, cheaper and faster than you can even get the raw material to your house,” says Jake Holland, vice president of manufacturing, SendCutSend.

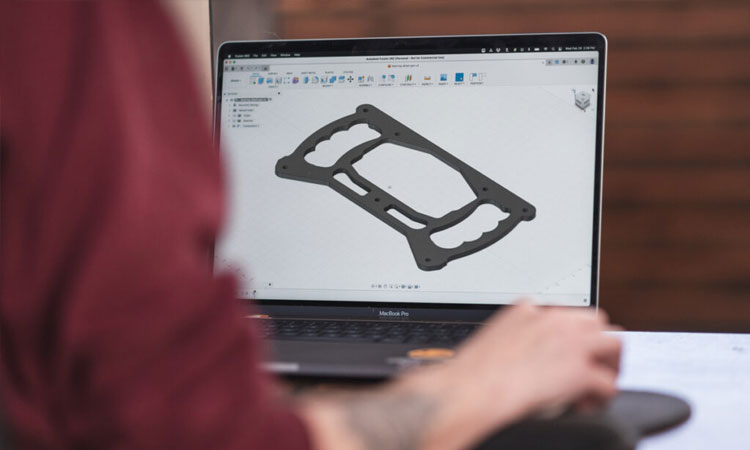

To get a part or product started, a customer simply uploads a DXF or STEP file for an instant quote on the website, then adds on options like CNC bending, powder coating, or PEM hardware, and then previews a 3D model. The final step is just a click to purchase, and it’s manufactured and shipped within a couple of days.

It turns out that this simplicity is equally attractive to Fortune 500 companies who began increasingly using SendCutSend within the first year. Now SendCutSend does anywhere from one-off, custom pieces to orders that have upward of 10,000 units.

“Fast forward to today and we do a big chunk of the Fortune 500, private space companies, defense, and everything in between,” Belosic says. “I always say my mom can make a sign for her kitchen that says ‘Live, Laugh, Love,’ but, at the same time, we have parts that are in orbit.”

SendCutSend’s manufacturing itself is also democratized. There’s no discrimination on order type. Everyone—from individuals and mom-and-pop shops to global manufacturers—uses the same web interface, receives the same service and machines, and the same quality, tolerance, materials, and certifications, no matter the run size.

Autodesk Fusion powers customers’ designs, manufacturing evaluations, and in-house innovations

Autodesk Fusion is an integral tool for the majority of SendCutSend’s customers. When SendCutSend receives an especially complex or difficult-to-manufacture order, they can quickly and easily evaluate the manufacturability in Fusion and provide any advice or guidance, when necessary, back to the customer. At the same time, SendCutSend uses Fusion to create custom designs for their own shop floor.

“We’re always building little gadgets to improve our work and efficiency,” Holland says. “We move a lot of orders around our shop. We have a tug system instead of a conveyor system because everything moves so differently. With Fusion, we were able to build a full train trailer setup, similar to what airlines use to move luggage.

“Having the CAM software built-in with the CAD software is essential,” he continues. “I don’t have to go back and forth between two different things. It’s just easy to use and, with the cloud, I can just open my computer at home, too. I use it every single day.”

To leverage SendCutSend’s business model and Fusion even further, the company recently developed a new plugin that enables customers to seamlessly review and order parts directly in Fusion itself. SendCutSend’s data is available for anyone to adjust their designs based on material, price, and other priorities directly in the software before placing an order. Accessing data within Fusion is transforming how customers can not only improve designs but also experience better outcomes.

“We can start to do more Design for Manufacturing (DFM) directly in Fusion and access its bend or material libraries for the plugin,” Belosic says. “You can get a ‘go’ or ‘no go’ right there in the software. It’s exciting to leverage this data and automation. It gives our customers the ability to make even better design and cost decisions before anything is ever cut.”

Embracing the future of manufacturing

As a company, SendCutSend is focused on taking a sustainable approach as much as possible. 99.99% of all waste metal from its manufacturing processes is recycled and sent to a mill to repurpose into future projects. Even a special dust-collection system is used to capture even the smallest specks of metal that result from laser cutting. To reduce their carbon footprint, they are diversifying manufacturing locations across the country to reduce shipping impact—and improve delivery times even further.

With SendCutSend’s growth, they are always looking to adopt Industry 4.0 practices even further. As AI continues to bring new innovations every day, the team is developing new approaches to incorporate throughout the company and its services.

“Where I want to go in the future is live recommendations and leveraging machine learning and AI,” Belosic says. “We’d love to give those recommendations of how to open a bend relief or prevent a collision in manufacturing. It’s complex, but it’s a lot of fun. It keeps me coming back.”

Visit : Autodesk Fusion