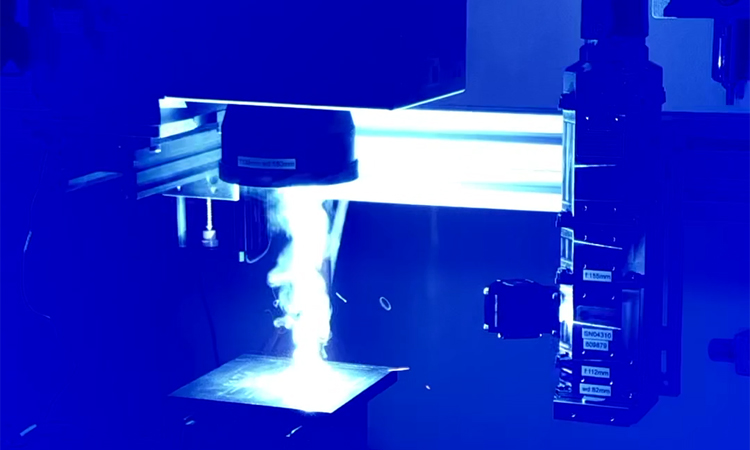

AMADA WELD TECH, a global leader in welding, marking, cutting, and bonding solutions, has introduced advanced blue diode laser technology to enhance micro welding applications. This innovation marks a significant step forward in welding efficiency, particularly for highly reflective materials like copper.

Traditional infrared lasers, such as Nd:YAG and fiber lasers, operate at wavelengths of 1064-1070 nanometers, which are poorly absorbed by copper, leading to high energy consumption and welding challenges. In contrast, blue lasers, operating at approximately 450 nanometers, provide superior absorption, enabling efficient energy utilization, reduced heat input, and minimal spatter. This results in greater precision and reliability in micro welding processes.

AMADA WELD TECH’s blue laser systems deliver power levels up to 1500 Watts, with potential scalability to 4000 Watts for industrial applications. Equipped to handle spot sizes between 200 to 500 microns, these systems are ideal for applications requiring delicate and precise joining, such as in the electronics, medical device, and automotive industries. Feasibility studies for customers are available at AMADA WELD TECH’s Western Technical Center in Monrovia.

“The integration of blue laser technology enhances our capability to weld challenging materials like copper, providing clients with unique solutions for improved production efficiency and throughput,” said Dr. Mark Boyle, Director of Product Engineering and Applications at AMADA WELD TECH.

This advancement underscores AMADA WELD TECH’s ongoing commitment to delivering innovative solutions tailored to the evolving demands of modern manufacturing.