Industrial workplaces often grapple with a hidden yet dangerous by product—machining oil mist. Generated during metal cutting, grinding, and milling processes, this mist not only jeopardizes worker health but also impairs workplace safety and efficiency. The adoption of advanced oil mist collectors, such as FilterON’s electrostatic systems, has become crucial for safeguarding health and enhancing productivity.

The Health Hazards of Oil Mist

Exposure to machining oil mist can lead to severe health consequences. Initially, it may irritate the eyes, nose, and throat, causing symptoms like burning, itching, sneezing, and coughing. While these effects may seem minor, prolonged exposure amplifies the risks, potentially leading to chronic respiratory conditions such as bronchitis and asthma.

More alarmingly, long-term exposure to oil mist has been linked to increased risks of lung cancer. This is due to the presence of harmful chemicals, including formaldehyde and benzene, which are classified as carcinogens. These substances accumulate in the lungs over time, posing a significant threat to workers’ health.

Minimizing Risks: The Role of Oil Mist Collectors

Implementing machining oil mist collectors is a proven strategy to combat these risks. These devices capture and eliminate airborne contaminants, improving air quality and protecting employees. Among various options, FilterON’s range of electrostatic oil mist collectors stands out for its innovative technology and superior performance.

The FilterON Advantage: Electrostatic Oil Mist Collectors

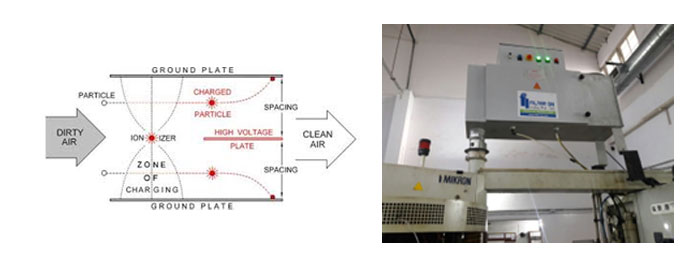

FilterON’s electrostatic oil mist collectors employ advanced technology to ensure exceptional air purification. Their operation involves using a high-voltage electrical charge to ionize oil mist particles, which are then drawn to grounded collector plates for easy removal.

Technical Advantages

- High Efficiency: Achieving removal rates of up to 99%, these collectors ensure a clean and safe workplace.

- Low Maintenance: Unlike traditional systems requiring frequent filter changes, FilterON’s devices are designed for minimal upkeep, with easy recovery or disposal of collected oil.

- Energy Efficient: Operating on minimal power, these systems are both cost-effective and environmentally sustainable.

- Compact Design: With their space-saving design, these collectors seamlessly integrate into existing workspaces, even in compact environments.

Key Benefits

- Improved Air Quality: By eliminating harmful oil mist particles, these collectors reduce the risk of respiratory illnesses among employees.

- Enhanced Safety: Cleaner air minimizes the risk of accidents caused by slippery floors and surfaces.

- Increased Productivity: A healthier, safer environment reduces absenteeism and boosts morale.

- Cost Savings: Long-lasting components and minimal maintenance translate into reduced operating costs.

Applications Across Industries

FilterON oil mist collectors are versatile, catering to diverse applications such as grinding (including 5-axis and tool grinding), sliding head machines, gear cutting, forging, and HMC/VMC setups. They are also invaluable for nut formers and centerless grinders, ensuring operational efficiency across various sectors.

A Commitment to Workplace Wellness

FilterON India Private Limited, under the leadership of Managing Director Manish Ghorpade, has pioneered solutions that not only protect workers but also enhance industrial productivity. By integrating their electrostatic oil mist collectors, companies can ensure a safer, healthier, and more efficient workplace.

For more information, visit www.filter-on.com