Metrology—the science of precise measurement—might not grab headlines, but it’s the silent force behind every flawless engine, every safe flight, and every reliable medical device. From aerospace to electronics, industries are demanding ever-tighter tolerances and faster feedback. As nations race toward smarter, more automated manufacturing, metrology has become a vital player in the push for precision. Here’s a look at how different countries are making strides in metrology—and which sectors are driving the demand.

Germany: Precision at the Core of Industrial Power

Germany, a global manufacturing heavyweight, is setting the pace in industrial metrology. With leaders like ZEISS and Wenzel, the country invests over 3% of its GDP in R&D, with a strong focus on measurement science.

Metrology here is not just about accuracy—it’s about efficiency. Real-time measurement systems are now integral to smart factories, particularly in the automotive, aerospace, and die & mould sectors. Coordinate measuring machines (CMMs), laser trackers, and form measuring equipment are standard on shop floors.

Sector Focus:

- Automotive: Inline metrology improves cycle times and reduces waste.

- Aerospace: Complex components require tight tolerances and 3D measurement.

- Tool & Die: High-precision moulds demand micrometer-level verification.

United States: Leading the Digital Metrology Revolution

In the U.S., the shift to digital and data-driven manufacturing is pushing metrology into the cloud. With industries like semiconductors, defense, and medical devices requiring near-zero-defect production, measurement systems must now do more than just inspect—they must analyze, predict, and improve.

Hexagon and FARO are pioneering AI-powered metrology software that combines 3D scanning, cloud storage, and real-time analytics. The National Institute of Standards and Technology (NIST) reports that metrology saves the economy more than $140 billion annually by improving quality and reducing errors.

Sector Focus:

- Semiconductors: Sub-micron metrology is critical for chip manufacturing.

- Defense & Aerospace: Inspection systems verify safety-critical parts.

- Medical Devices: High regulatory demands fuel growth in validation tools.

Japan: Blending Cultural Craftsmanship with Automation

Japan’s manufacturing culture, rooted in the concept of Monozukuri (the art of making things), places a premium on perfection. Companies like Mitutoyo and Nikon Metrology support industries with cutting-edge contact and non-contact systems.

Japan is a leader in robot-integrated metrology, where inspection systems are embedded directly into production robots. This is particularly common in electronics, machine tools, and automotive sectors, where compactness and speed are key.

📊 Key Stat: 85% of Japan’s precision shops use automated metrology.

Sector Focus:

- Electronics & Semiconductors: Small, dense parts need optical and tactile inspection.

- Machine Tools: CNC and EDM machines feature built-in measurement systems.

- Automotive: In-line systems ensure tight tolerances on mass-produced parts.

India: Fast-Growing Hub for Smart and Affordable Metrology

India’s metrology ecosystem is expanding rapidly, thanks to government initiatives like “Make in India” and the PLI scheme. This has led to rising demand across automotive, aerospace, electronics, and precision machining sectors.

With more than 2,000 NABL-accredited calibration labs and companies like ATQ Metro and Accurate Gauging providing locally-made, cost-effective solutions, India is combining affordability with innovation. Multinationals are also setting up shop to cater to the booming demand.

📈 Key Stat: The Indian metrology equipment market is projected to grow at a CAGR of 9.2% through 2029.

Sector Focus:

- SMEs in Manufacturing: Seeking compact, affordable, multi-sensor systems.

- Automotive & EVs: Ensuring part consistency and safety standards.

- Aerospace: Adoption of 5-axis CMMs and portable scanners.

China: Scaling Up for a Competitive Edge

China, the global factory floor, is undergoing a quality shift. The “Made in China 2025” initiative focuses heavily on precision and innovation in automotive, electronics, and heavy engineering.

While international brands like Renishaw and ZEISS operate in China, domestic players like Leader Metrology and AEH are supplying CMMs and 3D inspection systems tailored to local needs.

📊 Key Stat: China represents over 30% of global demand for CMMs.

Sector Focus:

- Automotive: Especially EVs, where lightweight materials require new inspection methods.

- Consumer Electronics: Demands high-speed, high-precision inspection.

- Energy Equipment: Growth in wind and solar components fuels need for large-scale measurement.

Italy & Spain: Innovating in Specialized Niches

Italy and Spain may not dominate in scale, but they shine in specialized, high-value sectors. Companies like Marposs (Italy) and R&D centers like Tekniker (Spain) are developing innovative metrology systems for tooling, aerospace, and high-performance automotive parts.

Spain’s expertise in surface metrology and Italy’s strength in in-process gauging help manufacturers maintain quality without slowing production.

Sector Focus:

- Precision Tooling: Ensuring form and finish quality in complex geometries.

- Aerospace Components: Adopting optical and tactile metrology.

- Medical Implants & Devices: Where surface integrity is critical.

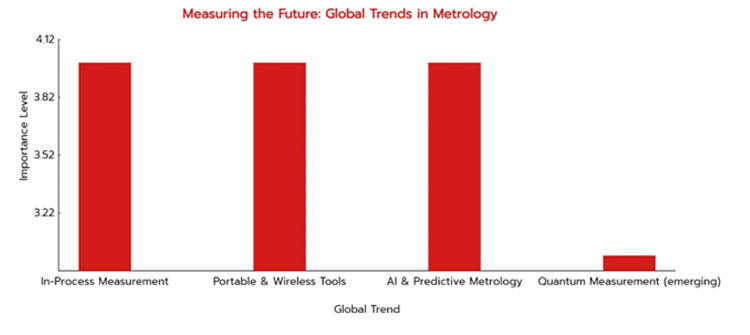

What’s Trending Globally in Metrology?

Across all borders and sectors, several trends are reshaping how metrology is applied:

- In-Process Metrology

Measuring during production—rather than after—saves time and reduces rework. - Portable and Wireless Tools

Handheld scanners and Bluetooth-enabled gauges support on-the-go inspection in modular setups. - AI and Predictive Analytics

Systems are learning from data to forecast defects before they occur. - Quantum Metrology (Emerging)

Promising unmatched precision for scientific labs and advanced industries.

A Micron-Sized Advantage That Makes a Big Difference

As global industries chase zero-defect goals, tighter tolerances, and higher throughput, metrology has moved from being a quality checkpoint to a strategic differentiator. Whether it’s Germany’s inline systems, America’s AI tools, Japan’s robotics, or India’s scalable solutions—every nation is finding its own way to measure up.

In the age of smart factories and global competition, those who master measurement will master manufacturing.