Mastercam Multiaxis offers a sophisticated set of toolpaths designed to unlock the full potential of simultaneous 4- and 5-axis machining. Available as an add-on to Mastercam Mill 3D, Router 3D, and Mill-Turn, this multiaxis toolkit delivers precision, efficiency, and versatility. As more machine shops adopt advanced multiaxis processes, Mastercam has continued to innovate. Here are eight standout features worth discovering:

Mastercam Multiaxis offers a sophisticated set of toolpaths designed to unlock the full potential of simultaneous 4- and 5-axis machining. Available as an add-on to Mastercam Mill 3D, Router 3D, and Mill-Turn, this multiaxis toolkit delivers precision, efficiency, and versatility. As more machine shops adopt advanced multiaxis processes, Mastercam has continued to innovate. Here are eight standout features worth discovering:

5-Axis Cutting with Wireframe Input

This toolpath allows users to generate complex 5-axis profiles using simple wireframe geometry—no need for machining surfaces. Found under the Unified toolpath, this feature provides greater control over tool motion using drive curves and tilt lines to define orientation. It’s a streamlined, flexible solution for high-precision cuts.

XYZ and Line Orientation Menu Enhancements

Improved naming conventions for X, Y, and Z directions, as well as corresponding Tplane options, simplify orientation setup and reduce programming time. These updates enhance toolpaths like Swarf Milling, Unified, Deburr, and Convert to 5-axis.

Include Tool Radius in Toolpath Calculation

Avoid manual calculations—this option automatically compensates for the tool radius inside or outside containment boundaries. You can still use the Additional Offset in combination, providing flexibility and accuracy.

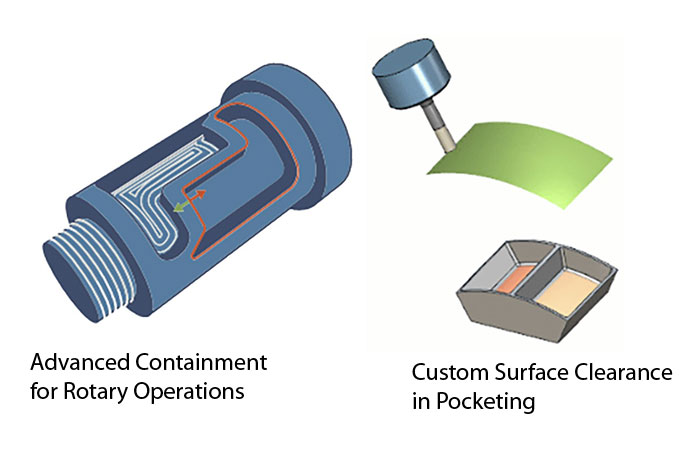

Advanced Containment for Rotary Operations

Rotary Advanced toolpaths now support containment curves, additional offsets, and inversion of containment areas. This allows precise control of machining boundaries with enhanced visual feedback during setup.

Tilt During Helix for Pocketing

This option orients the tool vector perpendicular to the slice during a helical entry, ensuring smoother transitions and reducing tool overload. It improves tool life and chip load consistency, offering a more efficient entry into roughing patterns.

Custom Surface Clearance in Pocketing

Users can define custom clearance surfaces—including spheres, cylinders, and planes—to control tool retracts and linking motion. This feature offers better safety and optimization for roughing toolpaths using both 3- and 5-axis outputs.

Swarf Milling: Tip or Flank Cutting Control

Swarf Milling now includes the option to cut using either the tool’s tip or flank, particularly useful for chamfer mills and edge-treated flat-end mills. This gives greater flexibility and precision depending on the part’s geometry and finish requirements.

Feed Rate Blending Control

The new Blending Distance setting lets users gradually transition feed rates into or out of control zones in Unified, Triangular Mesh, and Pocketing toolpaths. It enhances surface finish and tool wear control during speed transitions.

To learn more about how Mastercam Multiaxis can elevate your shop’s capabilities, visit: www.mastercamindia.com