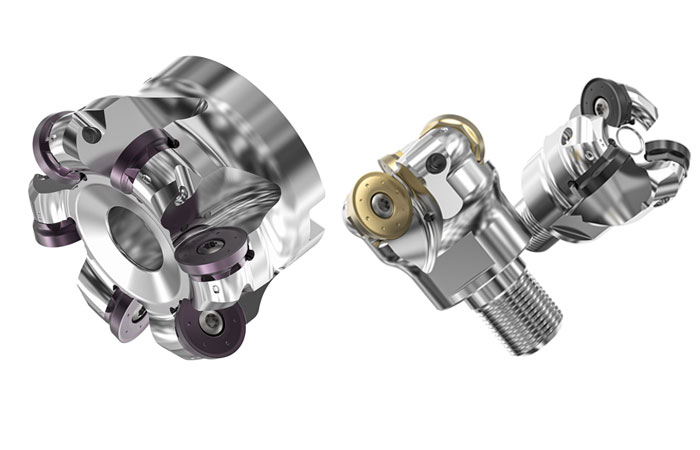

Seco Tools has launched the new generation of its Round 20 copy mills and inserts, designed to deliver exceptional performance across a broad spectrum of milling operations. Ideal for face, side, slot, plunge, and ramp milling, the latest Round 20 inserts are compatible with previous-generation cutter bodies while offering enhanced capabilities in handling challenging materials.

Versatile and Cost-Effective Milling Solution

The new Seco Round 20 cutters and inserts are optimized for medium-to-rough milling tasks, particularly in steel, stainless steels, and heat-resistant superalloys. Additionally, they perform effectively in cast iron and hardened steels, making them a versatile choice for diverse industrial applications. The large-diameter inserts enable high material removal rates, providing a cost-efficient method to produce an R10 mm radius using 20 mm round inserts.

Benoit Patriarca, Seco’s Product Manager, highlighted the evolution in this product line: “The new generation of Round 20 marks a significant advancement over earlier models. Today’s inserts can be indexed to four, six, or eight positions, giving users the flexibility to adjust insert consumption based on the depth of cut. Moreover, these new inserts seamlessly integrate with existing cutter bodies that index to four or eight positions, ensuring backward compatibility and versatility.”

Enhanced Cutter Body Durability and Efficiency

Seco has introduced insert shims and cassettes as part of the Round 20 system to prolong cutter body life. These features help reduce the risk of damaging insert pockets—a common cause of unexpected tool failure. By minimizing such damage, manufacturers can avoid costly replacements and prevent downtime associated with tool breakage.

The Round 20 product range now includes sixteen cutter bodies, supported by four shim options and three cassette options, along with thirty types of indexable cutting inserts. This broad selection allows manufacturers to tailor their tooling setup precisely to their machining needs, enhancing productivity and cost-effectiveness.

For the latest updates on innovations and Seco’s cutting-edge products, visit www.secotools.com.