“There is a great satisfaction in building good tools for other people to use.” – Freeman Dyson

The lathe, often regarded as the pioneer of modern machine tools, revolutionized manufacturing with its ability to perform turning operations. From its inception, turning has remained a cornerstone of machining processes, with lathes forming a significant part of the global inventory. Reflecting this legacy, turning tools occupy a large share of the product lines of leading cutting tool manufacturers.

In step with this, LOGIQUICK, ISCAR’s latest campaign, introduces groundbreaking developments in turning tools. These advancements enhance efficiency, precision, and profitability, while embracing the trends of modern metal cutting. Let’s explore the key focus areas in ISCAR’s campaign and the innovations transforming turning operations.

Key Features Defining Modern Turning Tools

- Higher Efficiency and Precision

Turning tools are now designed to increase machining speed, enhance accuracy, and minimize waste, delivering exceptional productivity. - Advanced Cutting Materials and Coatings

- Materials like ceramics and cubic boron nitride (CBN) provide unmatched heat resistance and durability, enabling faster cutting.

- Progressive coating technologies extend tool life and reduce wear, aligning with the demands of rapid metal removal.

- Multi-Directional Turning Tools

Multi-functional tools improve efficiency by reducing tool changes, decreasing downtime, and maintaining tight tolerances. - Digital Integration

The Industry 4.0 framework emphasizes digital capabilities in tools, making them essential for smart manufacturing setups. - Sustainability

Eco-friendly designs prioritize energy efficiency and reduced waste, addressing global environmental concerns.

Product Highlights from ISCAR’s Turning Innovations

- Advanced Cutting Materials

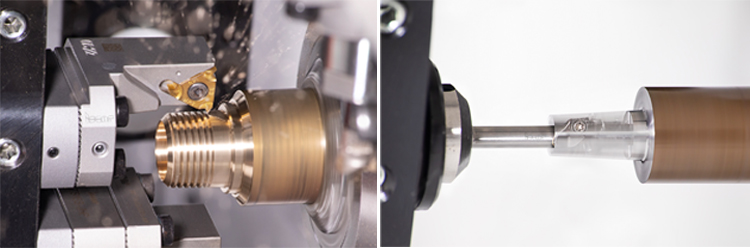

ISCAR’s new ceramic grades and carbide materials target challenging applications, such as machining hard steels, superalloys, and non-ferrous materials. Innovations like the IC1017 carbide grade and diamond-like coatings (DLC) exemplify this effort. - Multi-Directional Turning Solutions

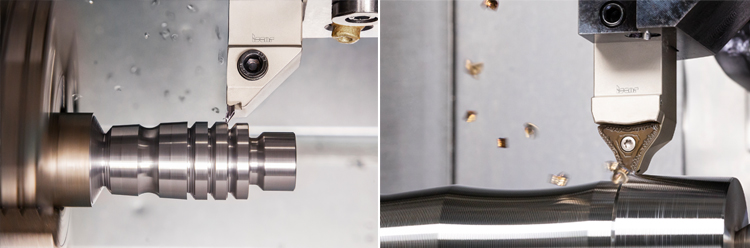

The QUICK-T-LOCK family supports multi-directional cutting operations with high stability and efficiency, while the CUT-V-GRIP inserts allow machining in areas unreachable by conventional tools. - Anti-Vibration Boring Tools

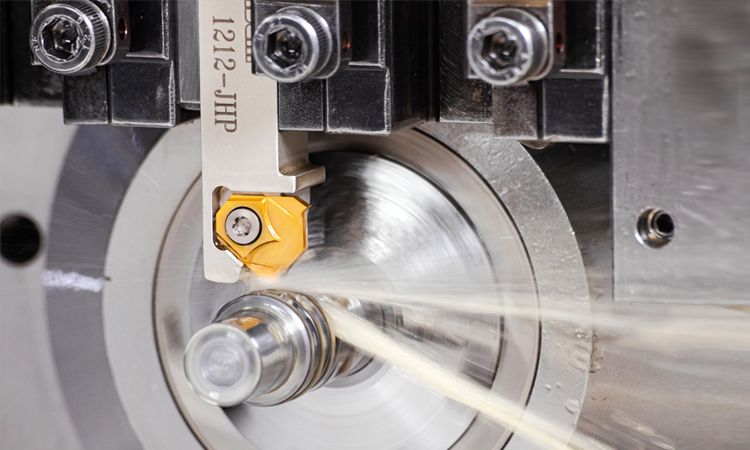

For high overhang boring, ISCAR’s anti-vibration holders with damping mechanisms enhance surface finish, tool life, and productivity. - Swiss-Type Machining

Dedicated solutions like the modular QUICKSWISS system and narrow QUICK-2-CUT inserts improve precision and efficiency in compact, multi-operation setups. The expansion of the LOGIQ-4-TURN family further addresses the needs of Swiss-Type lathes.

ISCAR’s LOGIQUICK campaign not only delivers cutting-edge tools but also reaffirms the importance of innovation in machining. These tools, engineered to boost productivity and profitability, echo a clear message to manufacturers: “Be quick to seize the advantages of advanced turning operations.”

By embracing these advancements, manufacturers can transform their operations, staying ahead in an increasingly competitive market.