In this insightful interview, B.V. Shyam, the Managing Director of Blum-Novotest Measuring & Testing Technology Pvt Ltd, shares his expertise and perspectives on the company’s growth, innovations, and strategic initiatives in the measurement technology industry. With a rich history and a strong commitment to quality and innovation, Blum-Novotest continues to lead the way in optical and tactile production measurement technology, catering to diverse industrial sectors globally.

How has BLUM achieved significant market growth in the measurement technology industry

Blum-Novotest, established in 1968, has carved out a notable presence in the global market. With over five decades of collaboration with machine tool manufacturers and end users, the company has consistently developed products and services that address industry challenges. BLUM stands at the forefront of optical and tactile production measurement technology for machine tools. Our technologies enhance productivity and the quality of manufactured parts across various industrial sectors, focusing on delivering fast, precise, and highly reliable products.

Can you describe BLUM’s global operations and network

Blum-Novotest is a global leader in measurement and testing technology, serving as a reliable partner to the machine tool, automotive, and aerospace industries. Our headquarters in GrĂĽnkraut, Germany, houses two manufacturing plants. We have a robust global presence with 18 subsidiaries and over 25 system integrators providing sales and services worldwide. We collaborate with machine tool manufacturers globally to ensure our innovations meet their needs.

What are BLUM’s key initiatives in measurement technology, and what are your focus areas

At BLUM, our key initiatives are driven by the need to stay ahead of industry advancements and meet the changing demands of our clients in the machine tools sector. We continuously innovate to introduce cutting-edge technologies that enhance precision and efficiency. One of our standout innovations is the Digilog technology, which significantly improves measurement speed, accuracy, and reliability for both tools and workpieces. This technology exemplifies our commitment to pushing the boundaries of what’s possible in production measurement.

What opportunities does the Indian market hold for BLUM products, and how do you plan to position them

Having operated in India for over 16 years, Blum-Novotest has a solid presence with offices in Bangalore, Pune, Delhi, Chennai, and Ahmedabad, complemented by a network of channel partners in key industrial hubs. India is a vital market globally, catering to sectors such as machine manufacturing, automotive, aerospace, die & mould, medical, electronics, toy manufacturing, and heavy industries. We are particularly focused on the MSME sector, where we aim to enhance productivity and optimize investments through our dependable products and robust industry support.

What is your marketing strategy for the Indian market

Our marketing strategy is simple yet effective: maintain close relationships with our customers and deliver high-quality, reliable products. We achieve high customer retention by offering exceptional service and prompt support. Additionally, we utilize exhibitions, seminars, and various media channels to connect with our audience. Conducting test installations also helps us build customer confidence in our technologies..

How has R&D contributed to the success of BLUM products

Our dynamic R&D team plays a crucial role in our success by focusing on forward-thinking product development. This approach ensures that we stay ahead of technological advancements in the manufacturing industry.

Can you elaborate on your quality policy

Our commitment to quality is reflected in our stringent policies. We prioritize maintaining high in-house production depth, ensuring that our manufacturing processes are robust and controlled within our facilities. Equipped with modern production technologies, we strive to uphold the highest standards of quality throughout every stage of production. Central to our approach is the rigorous application and testing of BLUM products in our own manufacturing processes.

This ensures that our products not only meet but exceed the expectations of our customers, delivering reliability and performance. By integrating BLUM products into our production, we validate their durability and functionality firsthand, reinforcing our dedication to excellence. Our quality policy serves as the cornerstone of our operations, guiding us to consistently deliver products that embody innovation, reliability, and uncompromising quality.

What are BLUM’s hero products range, kindly elaborate more about the same

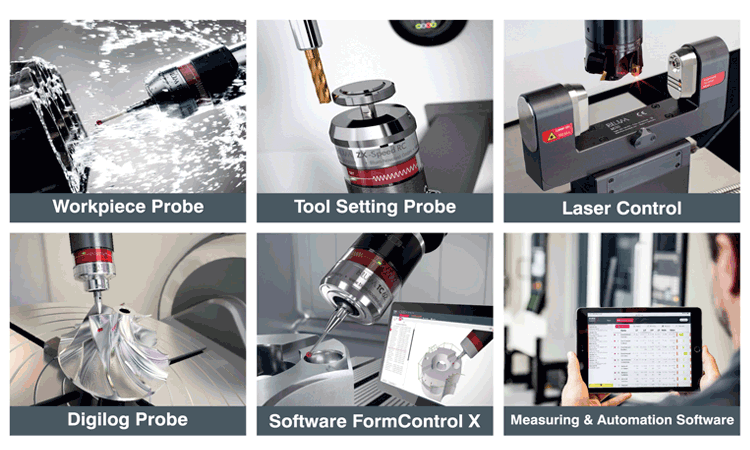

Our top-tier products include:Â

DIGILOG Technology: Combines digital and analogue touch probe functionalities in a single device.

LC50-DIGILOG: A cutting-edge laser measuring system for CNC machining centers, known for its speed, precision, and reliability.

TC76/63/64: DIGILOG touch probes for rapid, automatic inspection of workpiece contours in mass production.

BLUM Laser MicroCompact NT: Leading non-contact tool setting and monitoring laser measuring systems for CNC machining centers.

BLUM Z-Series: Tactile tool probes for fast, automatic tool setting and breakage monitoring in harsh machine tool environments.

BLUM-TC Series: Probes for fast, automatic workpiece measurement and zero-point detection in machine tools.

BLUM Form Control: User-friendly 3D inspection software for quality control of free-form surfaces and geometric elements in CNC machining centers.

What are the strengths of the Indian measurement technology industry, and how does it compare globally

The Indian manufacturing industry has successfully integrated advanced measurement technologies, aligning with global standards. There is significant potential for further expansion in India.

In your opinion, what technological trends are driving the measurement technology industry

Key trends include advancements in manufacturing, the integration of IoT, and the adoption of Industry 4.0. Initiatives such as “Make in India” and “AatmaNirbhar Bharat” are also propelling efficiency, reproducibility, and productivity in the manufacturing sector. Our production metrology systems are specifically designed to address these evolving demands.

What issues need addressing in the measurement technology industry

To meet industry demands, we aim to expand our network to reach a broader customer base. We plan to increase awareness and adoption of our technologies by showcasing them through exhibitions, seminars, and electronic media.

BLUM’s dedication to innovation and quality in optical and tactile production measurement technology continues to fuel its global success, solidifying the company’s leadership in this vital industry.