Advanced CAE solutions offer tools that enhance product performance and optimize designs across industries like railways and heavy engineering. They can address multitude challenges in the areas of structural analysis, fluid dynamics, thermal simulations and many more, that are crucial for designing and validation of heavy locomotives and railway coaches.

Advanced CAE solutions offer tools that enhance product performance and optimize designs across industries like railways and heavy engineering. They can address multitude challenges in the areas of structural analysis, fluid dynamics, thermal simulations and many more, that are crucial for designing and validation of heavy locomotives and railway coaches.

Some of the critical challenges addressed by CAE are:

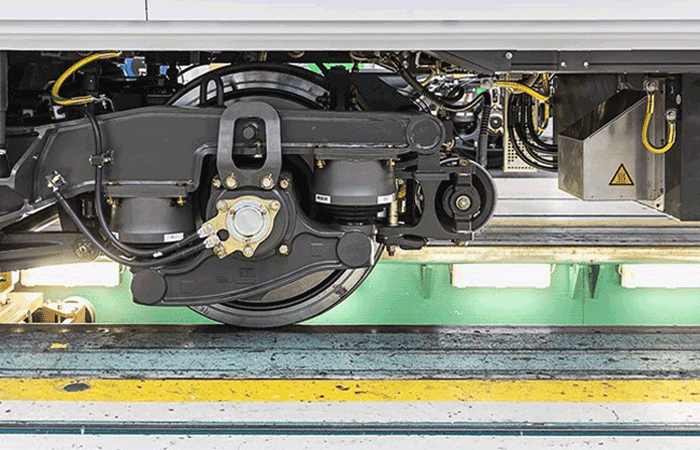

- Underframe and Bogie Design Validation

- Crashworthiness Evaluation (EN 15227)

- Lightweight Design using innovative materials

- Electromagnetic Compatibility

- Weld Strength Analysis

By enabling sophisticated engineering approaches, CAE validation ensures modern trains meet high standards of comfort, reliability, and safety.

Altair Engineering is one of the leading CAE solutions companies in the world. In the realm of heavy engineering, Altair’s solutions extend beyond railways to optimize the design of heavy machinery and equipment. As companies strive to create sustainable designs, CAE tools for design optimization enable the assessment of ideal material distribution and the exploration of alternative materials. This design optimization process not only results in lighter, more robust machinery but also contributes to improved energy efficiency.

Additionally, Altair’s multiphysics simulation capabilities allow engineers to conduct various tests on a single platform, streamlining the design process and reducing time-to-market. By integrating CAE solutions into the lifecycle management of heavy engineering products—from concept to decommissioning—Altair plays a pivotal role in enhancing product development and quality assurance.

Altair’s advanced CAE solutions are transforming the railway and heavy engineering sectors by enabling manufacturers to optimize designs, enhance safety, and achieve higher sustainability. By leveraging simulation technologies, companies can navigate the complexities of modern engineering challenges, ultimately delivering innovative solutions that meet the demands of a rapidly evolving industry.

CASE STUDIES :

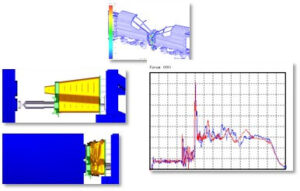

Energy Absorption Systems: Enhancing Safety for High-Speed Trains

The challenge of developing an energy absorption system to meet new European safety requirements for high-speed trains led to innovative solutions in crash safety. Altair’s RADIOSS software was employed for crash simulation, allowing engineers to analyze and calibrate test results against simulation data.

To optimize performance, HyperStudy was utilized for design variations, simulating various impact scenarios, including:

- AGV (Automated Guided Vehicle) vs. AGV

- AGV vs. freight wagon

- AGV vs. deformable obstacles

Through these simulations, engineers were able to assess the effectiveness of the energy absorption systems under different conditions, ensuring compliance with stringent safety regulations. The results confirmed that the AGV met all necessary safety standards, with the entire energy absorption occurring in the front section of the train.

This comprehensive approach not only enhanced the safety of high-speed trains but also set a new benchmark for energy absorption systems in the rail industry, demonstrating the vital role of advanced simulation tools in meeting evolving safety requirements.

Emerging trends like digital twin technology, AI, and machine learning are revolutionizing CAE applications. Digital twins provide real-time performance data and predictive maintenance, reducing machine downtime. AI-driven physics simulations simplify complex analyses, enhancing productivity and accelerating product development, ensuring companies stay ahead of challenges in the industry.

General Manager Sales

Railway & Heavy Engineering Machining