In industries like aerospace, automotive, energy, and medical devices, hard-to-machine materials such as titanium, Inconel, and composites are increasingly being used for their superior properties. Titanium’s high strength-to-weight ratio, Inconel’s heat resistance, and composites’ lightweight versatility make them indispensable for critical applications. However, these materials present unique machining challenges, including rapid tool wear, excessive heat generation, and maintaining tight tolerances. Overcoming these issues demands advanced tools, innovative techniques, and a deep understanding of material behavior.

The Growing Market for Exotic Materials

The global titanium market is projected to grow at a CAGR of 5.7% between 2023-24 and 2030, driven largely by demand from the aerospace sector, where fuel-efficient aircraft are a priority. Similarly, the global Inconel market is expected to grow at 6.2% annually, propelled by its use in jet engines, gas turbines, and automotive exhaust systems. Composite materials, particularly carbon fiber-reinforced polymers, are witnessing rapid adoption, with the global market forecasted to exceed USD 30 billion by 2028.

In India, sectors like defense and renewable energy are increasingly leveraging these materials. However, machining them remains a bottleneck, requiring tailored solutions to enhance efficiency and reduce costs.

Challenges in Machining

- Titanium: Known for its low thermal conductivity, titanium retains heat near the cutting zone, accelerating tool wear. Its elasticity also causes “spring back,” affecting precision.

- Inconel: A nickel-based superalloy, Inconel is tough, abrasive, and prone to work hardening, requiring meticulous control of cutting parameters.

- Composites: Composites are challenging due to their heterogeneity, causing delamination, fiber pull-out, and excessive tool wear when machined.

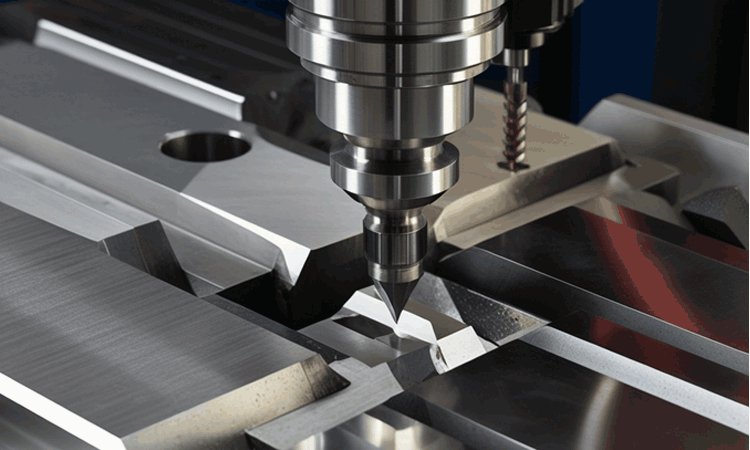

Tools and Techniques for Success

Advanced Tooling Materials

- Carbide Tools: Preferred for titanium, carbide tools with sharp edges and heat-resistant coatings reduce cutting forces and improve tool life.

- CBN (Cubic Boron Nitride) and PCD (Polycrystalline Diamond) Tools: These are ideal for machining composites, offering superior wear resistance and reduced delamination risks.

- Ceramic Tools: Highly effective for Inconel, ceramic tools can withstand extreme temperatures and reduce cycle times.

Coatings and Geometries

- Titanium machining benefits from AlTiN or TiAlN-coated tools, which offer excellent heat resistance and minimize tool wear.

- Optimized geometries, such as variable-helix designs, enhance performance by reducing vibration and chatter during cutting.

Cooling and Lubrication

- High-Pressure Coolant Systems: Essential for Inconel and titanium, these systems prevent heat buildup, improve chip evacuation, and extend tool life.

- Minimum Quantity Lubrication (MQL): Effective for composites, MQL ensures better surface finishes while reducing environmental impact.

Innovative Machining Strategies

- High-Speed Machining (HSM): Reduces heat generation in titanium and Inconel, ensuring better tool life and higher productivity.

- Cryogenic Machining: Particularly effective for Inconel, it uses liquid nitrogen to cool the cutting zone, minimizing thermal damage.

- Multi-Axis CNC Machining: Crucial for composites, multi-axis systems enable precise cuts while avoiding delamination.

Industry Success Stories

Global leaders like Boeing and Rolls-Royce have reported significant improvements in machining efficiency by adopting advanced tools and techniques. In India, companies like Bharat Forge and Hindustan Aeronautics Limited are investing heavily in R&D to develop localized machining solutions for exotic materials, enhancing their global competitiveness.

Machining hard-to-machine materials is a complex but rewarding endeavor, enabling manufacturers to harness the full potential of titanium, Inconel, and composites. With advanced tools, coatings, and machining strategies, the cutting tools industry is rising to the challenge, paving the way for innovation across critical sectors. As the demand for these materials continues to grow, investing in cutting-edge solutions will remain key to driving efficiency and precision in machining operations.