In the ever-evolving landscape of automotive manufacturing, globalization has emerged as a driving force reshaping the way vehicles are designed, produced, and assembled. The impact of globalization on automotive machining is profound, touching upon various aspects from supply chains to technological advancements and market dynamics.

Supply chain impact :

One of the most significant effects of globalization on automotive machining is the transformation of supply chains. With the expansion of global trade networks, manufacturers have gained access to a wider range of materials, components, and technologies from around the world. This has led to increased competition and greater opportunities for collaboration among suppliers, fostering innovation and driving efficiency in machining processes. Furthermore, globalization has fostered greater collaboration among suppliers, as they work together to meet the evolving needs of the global automotive market. This collaboration has led to innovation in machining processes, driving improvements in efficiency, quality, and cost-effectiveness.

However, the globalization of supply chains has also introduced new challenges, such as increased complexity and vulnerability to disruptions. Manufacturers must now navigate a global web of suppliers, which can make supply chains more susceptible to disruptions such as natural disasters, geopolitical tensions, and trade disputes. Overall, the transformation of supply chains due to globalization has reshaped the automotive machining industry, leading to both opportunities and challenges for manufacturers and suppliers alike.

Adoption of cutting-edge machining technologies

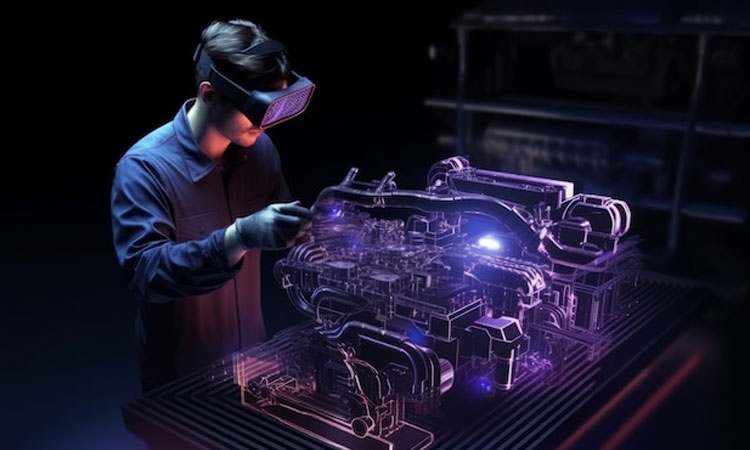

Globalization has triggered a surge in the adoption of cutting-edge machining technologies within the automotive industry. In response to heightened competition in the global market, manufacturers are increasingly investing in state-of-the-art equipment such as CNC machines, robotics, and automation systems. These investments are aimed at boosting productivity, enhancing precision, and improving flexibility in machining operations.

This technological revolution has transformed the manufacturing landscape, ushering in higher quality standards and shorter production lead times. Advanced CNC machines enable intricate machining operations with unparalleled precision, while robotics and automation systems streamline processes, reducing manual labor and minimizing errors.

Furthermore, the integration of these advanced technologies allows manufacturers to adapt swiftly to changing market demands and customer preferences. With the ability to produce parts more efficiently and accurately, automotive companies can maintain their competitive edge in the global marketplace.

The adoption of advanced machining technologies driven by globalization has revolutionized the automotive industry, paving the way for greater efficiency, precision, and innovation in the manufacturing of automotive parts.

Knowledge Exchange :

Globalization has played a pivotal role in fostering the exchange of knowledge and expertise in automotive machining across international borders. Collaborative efforts between manufacturers, academic institutions, and technology providers have led to accelerated innovation in the field. By pooling resources and sharing insights, these partnerships have facilitated the development of cutting-edge machining techniques and materials.

This cross-pollination of ideas has not only fueled continuous improvement in automotive machining processes but has also driven the creation of next-generation vehicles with enhanced performance and fuel efficiency. The collective efforts of industry stakeholders have resulted in breakthroughs that push the boundaries of what is possible in automotive engineering.

Challenges :

Globalization’s transformative influence on automotive machining is accompanied by a host of challenges that cast a shadow over the industry’s progress. While outsourcing machining jobs to low-cost regions promises economic benefits, it also triggers concerns about job displacement and the decline of domestic manufacturing prowess in certain nations. The allure of cost savings often comes at the expense of local employment opportunities and the erosion of skilled labor forces, sparking debates about the social implications of globalization.

Moreover, the intricate web of global supply chains, while enhancing efficiency and accessibility, exposes manufacturers to heightened vulnerability. Natural disasters, geopolitical tensions, and trade disputes loom as looming threats, capable of disrupting the seamless flow of materials and components. The fragility of these supply chains underscores the importance of resilience and risk management strategies in safeguarding the automotive industry against potential disruptions.

Amidst these challenges, automotive manufacturers are compelled to navigate a delicate balance between cost efficiency and sustainability. The pursuit of lower production costs through outsourcing must be tempered with considerations for social responsibility and environmental impact. Similarly, while global supply chains offer unparalleled access to resources, they demand meticulous planning and mitigation strategies to mitigate the risks posed by external factors.

In this complex landscape, resilience emerges as a critical virtue, enabling automotive manufacturers to weather the storms of globalization while remaining steadfast in their commitment to quality, innovation, and social responsibility. As the industry grapples with the multifaceted implications of globalization, the journey towards sustainable growth and prosperity demands a nuanced approach that balances economic imperatives with ethical considerations.

Globalization has left an indelible mark on the landscape of automotive machining, ushering in an era of unprecedented change and transformation. The influence of globalization is evident in the realm of technological innovation, where advancements in machining techniques and materials have propelled the industry forward, enhancing efficiency and quality standards.

Moreover, globalization has fostered greater collaboration among industry stakeholders, facilitating the exchange of knowledge and expertise across borders. This collaborative spirit has led to the development of cutting-edge solutions and the emergence of new market opportunities, driving growth and prosperity in the automotive machining sector.

Brighter Future :

However, the journey towards globalization has not been without its challenges. The outsourcing of manufacturing jobs to low-cost regions has raised concerns about job displacement and the erosion of domestic manufacturing capabilities. Additionally, the increasing complexity of global supply chains has made manufacturers more vulnerable to disruptions, necessitating a heightened focus on resilience and risk management.

Nevertheless, despite these challenges, globalization has opened up new avenues for growth and development, paving the way for a more interconnected and dynamic automotive industry. As the industry continues to evolve, embracing the opportunities presented by globalization while addressing its challenges will be key to ensuring a prosperous future for automotive machining. Through collaboration, innovation, and a commitment to resilience, the industry is well-positioned to meet the challenges of the future and thrive in an increasingly globalized world.

image courtesy : Designed by Freepik