In the realm of railway maintenance and construction, efficiency, precision, and safety are paramount. Among the arsenal of tools aiding in these endeavours, vacuum lifters stand out as versatile solutions for handling various materials and components.

When it comes to installing or replacing window glass panels in railway carriages or station structures, precision and safety are essential. The Schmalz VM Window 200 vacuum lifter excels in handling glass panels vertically, ensuring secure attachment and smooth manoeuvrability. Its specialized design allows for seamless vertical-to-vertical transfers, minimizing the risk of damage or accidents during installation.

Similarly, in the vertical transfer of railway doors, the VM Window 200 vacuum lifter proves invaluable. Whether it is for maintenance or replacement purposes, this lifter offers precise control and secure grip, facilitating seamless door installations or removals without compromising safety or efficiency. Railway infrastructure often involves the installation or refurbishment of wall panels in stations, depots, or other facilities. The Schmalz VM Basic 500 90 vacuum lifter is tailor-made for handling such panels, transitioning them from a horizontal to vertical orientation with ease. Its sturdy construction and adjustable gripping mechanisms ensure reliable performance, even with large or irregularly shaped panels.

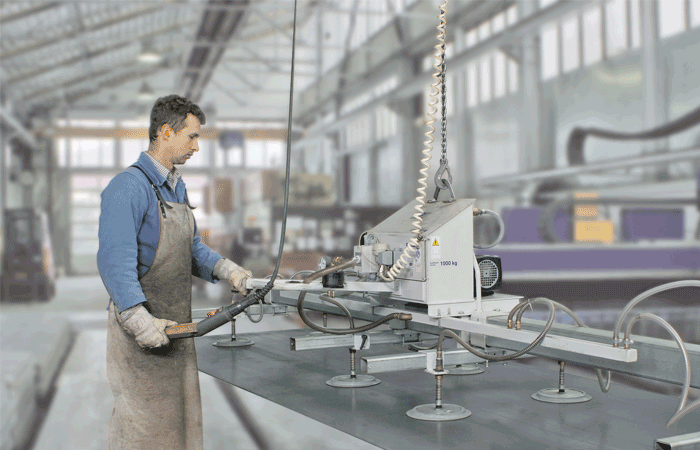

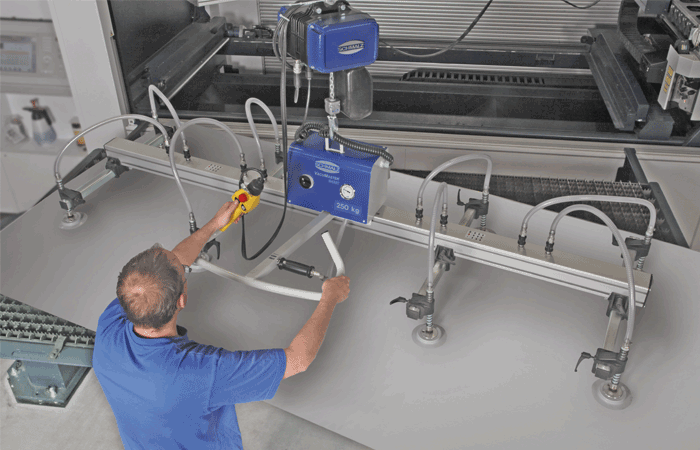

In railway workshops or fabrication units, laser or plasma cutting machines play a crucial role in shaping sheet metal components for various applications. Schmalz Vacuum lifters like the VM 500/750 or VM Vario 1000/2000 excel in loading raw sheet metal horizontally onto these machines. Their robust design and customizable configurations allow for efficient handling of heavy-duty metal sheets, optimizing production workflows with precision and speed.

Sheet metal bending is a common process in railway manufacturing, where precision is paramount for ensuring the structural integrity of components. Schmalz Vacuum lifters such as the VM 500/750 are adept at horizontally loading sheet metal onto bending machines. With their secure grip and

ergonomic controls, they facilitate smooth and accurate positioning of metal sheets, streamlining the bending process and minimizing downtime.

In conclusion, Schmalz vacuum lifters offer a versatile and reliable solution for a wide range of applications in railway maintenance and construction. From handling delicate glass panels to manoeuvring heavy-duty sheet metal, these specialized tools enhance efficiency, precision, and safety across various tasks within the railway industry, ultimately contributing to smoother operations and improved infrastructure quality.