Interior and exterior parts machining is at the forefront of automotive manufacturing, encompassing the intricate processes involved in crafting components such as dashboards, panels, and body frames. These components not only contribute to the aesthetics of vehicles but also play a crucial role in enhancing functionality and user experience. As automotive design evolves to meet the demands of discerning consumers, the interior and exterior parts machining sector is witnessing several trends that are reshaping the landscape of component production.

Advanced Materials Adoption:

The demand for innovative design and lightweight construction is driving the adoption of advanced materials in interior and exterior parts machining. Manufacturers are increasingly utilizing materials such as carbon fiber composites, aluminum alloys, and engineered plastics to achieve a balance between aesthetics, durability, and weight reduction. These materials offer greater design flexibility, improved structural integrity, and enhanced resistance to corrosion and wear.

Customization and Personalization:

Consumer preferences for personalized vehicles are fueling demand for customizable interior and exterior components. Machining processes are evolving to accommodate bespoke design features, intricate patterns, and personalized finishes. Advanced CNC machining techniques and digital design software enable manufacturers to produce custom components tailored to individual preferences, allowing for greater creativity and personalization in automotive design.

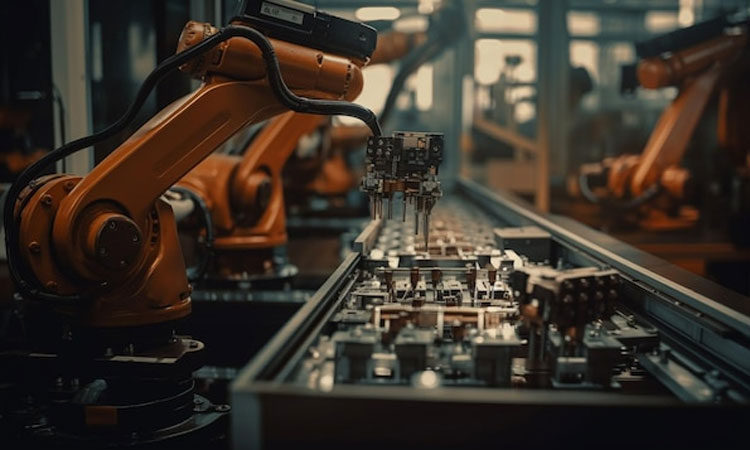

Integration of Advanced Technologies:

The integration of advanced technologies such as 3D printing, laser cutting, and robotic assembly is revolutionizing interior and exterior parts machining processes. 3D printing enables rapid prototyping and production of complex geometries, allowing for greater design freedom and innovation. Laser cutting and precision machining techniques ensure high-precision fabrication of intricate components, while robotic assembly enhances efficiency and consistency in production.

Sustainable Manufacturing Practices:

Environmental sustainability is a key focus area for automotive manufacturers, driving the adoption of sustainable machining practices in interior and exterior parts production. Machining companies are embracing eco-friendly materials, energy-efficient processes, and waste reduction strategies to minimize environmental impact. Recyclable materials, bio-based plastics, and water-based coatings are being increasingly utilized to reduce carbon footprint and promote a circular economy in automotive manufacturing.

Connectivity and Smart Features:

The rise of connected vehicles and smart technologies is influencing interior and exterior parts design and machining. Components such as infotainment systems, touchscreen displays, and sensor-integrated panels are becoming commonplace in modern vehicles, requiring specialized machining processes to accommodate electronics and connectivity features. Machining companies are investing in advanced tooling and automation to produce smart components that seamlessly integrate with vehicle electronics and enhance user experience.

Emphasis on Safety and Comfort:

Interior and exterior parts machining trends are increasingly focused on enhancing safety, comfort, and ergonomics in vehicle design. Components such as airbag housings, impact-absorbing panels, and ergonomic seating systems require precision machining to meet stringent safety standards and ensure occupant protection. Additionally, noise-reducing materials, vibration-damping structures, and thermal insulation features contribute to a quieter, more comfortable driving experience.

Interior and exterior parts machining is undergoing a period of rapid innovation driven by advancements in materials, customization capabilities, technology integration, sustainability practices, and safety considerations. Manufacturers that embrace these trends and invest in cutting-edge machining processes will be well-positioned to meet the evolving demands for aesthetically pleasing, functional, and sustainable automotive components that enhance the overall driving experience.

image courtesy : Designed by Freepik