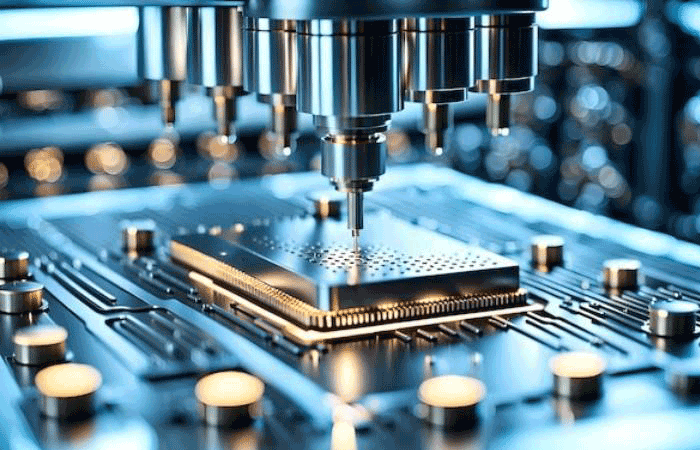

In the rapidly advancing semiconductor industry, the demand for precision and efficiency is at an all-time high. Recent innovations in tooling and machining equipment are pivotal in addressing these challenges, particularly through enhancements in cutting tools and the integration of smart technologies.

High-Performance Cutting Tools

Cutting tools are fundamental to semiconductor machining, where the need for precision and durability is paramount. One of the most significant advancements is the development of diamond-coated tools. These tools feature a diamond layer that enhances hardness and wear resistance, making them exceptionally effective for machining hard and brittle semiconductor materials. The diamond coating ensures that the tools maintain their sharpness over extended periods, which is crucial for achieving the fine tolerances required in semiconductor manufacturing.

Moreover, the field of high-speed machining has seen substantial progress. High-speed machining techniques enable faster material removal rates while maintaining high levels of precision. This innovation reduces machining time and enhances overall productivity. By increasing the cutting speeds and optimizing the tool paths, manufacturers can achieve more efficient production cycles without compromising the quality of the semiconductor components.

Smart Machining Equipment

The integration of smart technologies into machining equipment represents a transformative shift in the industry. Modern machining systems are increasingly equipped with sensors that monitor real-time parameters such as temperature, vibration, and tool wear. These sensors provide critical data that enables predictive maintenance, which helps prevent unexpected equipment failures and extends the lifespan of the tools. By analyzing sensor data, manufacturers can perform timely maintenance, reducing downtime and ensuring continuous operation.

Automation is another key component of smart machining equipment. Advanced automation systems enable precise control of machining operations, minimizing the potential for human error. Automated systems can adjust machining parameters dynamically based on real-time data, ensuring consistent quality and precision throughout the production process. This integration of automation not only improves accuracy but also enhances operational efficiency.

Additionally, sophisticated software algorithms are used to analyze data collected from sensors. These algorithms optimize machining processes by adjusting parameters such as feed rates and cutting speeds in real-time. This dynamic adjustment helps maintain high precision and quality while adapting to changing conditions in the manufacturing environment.

Innovations in high-performance cutting tools and smart machining equipment are driving significant improvements in semiconductor machining. By leveraging diamond-coated tools and high-speed machining techniques, alongside integrating smart technologies such as sensors and automation, manufacturers can achieve superior precision, efficiency, and reliability. These advancements are essential for meeting the demanding requirements of modern semiconductor production and paving the way for the next generation of electronic devices.

Image courtesy : Design by Freepik