As the automotive industry shifts rapidly toward electrification, manufacturers face new challenges in precision machining, materials, and production efficiency. ISCAR, a global leader in cutting tool technologies, is driving this transformation by offering advanced metalworking solutions tailored specifically for electric vehicle (EV) production.

Public demand for cleaner environments and global emission regulations are accelerating the shift away from internal combustion engines. EVs are no longer just a future concept—they are today’s reality. Producing electric vehicles requires a rethinking of traditional manufacturing methods to meet the needs of lightweight materials, high-precision components, and clean energy efficiency.

Advanced Tooling for New Challenges

EV production involves specialized components such as battery housings, electric motors, and lightweight chassis parts. ISCAR provides state-of-the-art solutions to address the unique machining requirements of these components, using advanced materials, precision engineering, and a deep understanding of EV manufacturing.

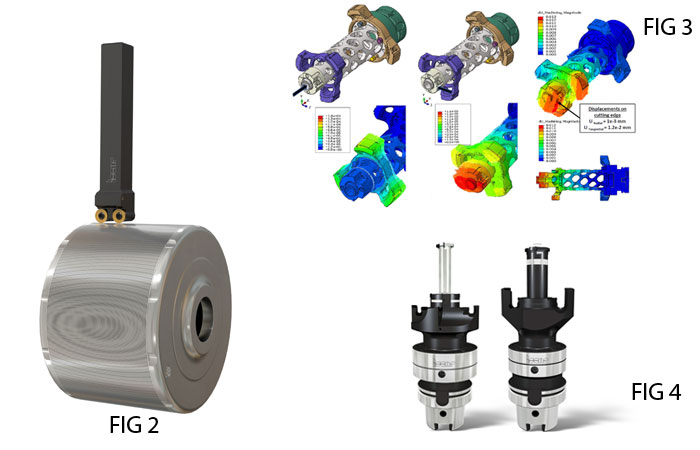

ISCAR’s R&D team evaluates the most productive machining options—from boring and contouring to finishing—often using PCD-tipped tools for optimal cycle time, surface finish, and tool performance. These tools are designed to meet the demanding standards of the automotive sector.

Milling Excellence

- MULTI-MASTER Heads: Interchangeable solid carbide heads designed for aluminum and composite machining, offering quick tool changes with no setup time—ideal for EV battery enclosures and chassis parts.

- HELIALU & HELI2000 Indexable Mills: Deliver superior surface finish and tool life for high-efficiency aluminum machining, essential for lightweight EV components.

Precision Turning

- ISO-Type Inserts: Engineered for clean and accurate machining of electric motor components, especially rotor parts where coolant use is restricted.

- ALU-P-TURN: Indexable turning tools optimized for aluminum, ensuring high-volume, consistent production.

- CUT-GRIP & SELF-GRIP: Parting, grooving, and threading tools ideal for complex EV assembly geometries.

- TANG-GRIP: High clamping stability reduces setup time, boosting productivity in grooving operations.

Holemaking Innovations

- SUMOCHAM Drills: Modular drills with exchangeable solid carbide heads, offering fast penetration rates and superior chip evacuation—perfect for non-ferrous EV materials.

- BAYO T-REAM: Customizable PCD-tipped reamers for high-speed, high-precision finishing in aluminum components.

Smart Coatings and Simulation

For aluminum and non-ferrous materials, diamond-like carbon (DLC) coatings enhance tool life and performance. ISCAR’s use of Finite Element Method (FEM) in tool design also helps predict performance and optimize cutting strategies before production begins.

Committed to Sustainability

ISCAR’s tools are engineered to minimize waste, reduce energy consumption, and support eco-friendly manufacturing. Their efficient solutions contribute to greener production while maintaining the highest quality standards.

Partnership for Success

Beyond tooling, ISCAR collaborates closely with manufacturers to provide tailored solutions and technical support, ensuring each EV production line reaches its goals for precision, speed, and sustainability.

As the global EV market expands, ISCAR remains a trusted partner, helping manufacturers drive the future of mobility with smarter, cleaner, and more efficient machining solutions.

For more information, visit ISCAR’s website or contact their expert team.