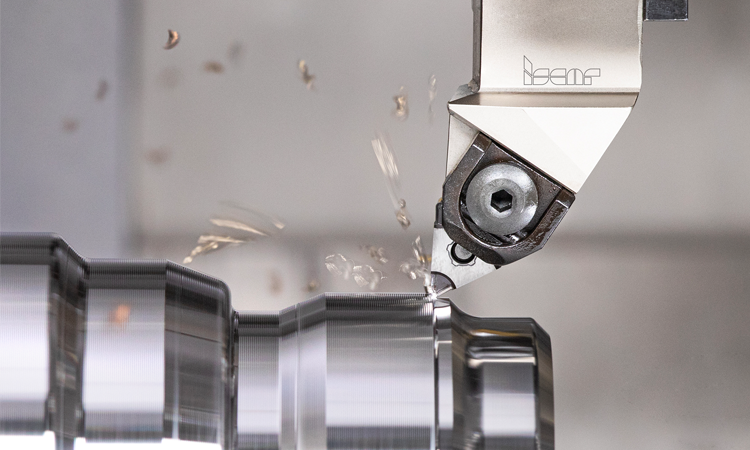

ISCAR is set to revolutionize metal cutting with the launch of LOGIQUICK, a new product line that integrates the concepts of “Logic,” “IQ,” and “Quick.” Building on its history of delivering intelligent cutting tools for advanced machining, ISCAR’s new campaign emphasizes fast and efficient machining, providing logical solutions for modern production. With the addition of Quick, the company is set to push the boundaries of productivity, raising expectations for future tools.

In metal cutting, productivity hinges on metal removal rates (MRR), which are essential for efficient machining. The industry’s focus on “fast metal removal” requires cutting tools that can remove material swiftly while maintaining precision. Despite advances in machine tools and strategies, cutting tools often remain the bottleneck, limiting productivity, increasing costs, and affecting profitability.

ISCAR aims to produce cutting tools that not only enhance metal removal rates but also offer repeatability, versatility, user-friendliness, and durability. These qualities represent the “IQ” of the tools, maximizing the potential of modern machine tools. This vision guides ISCAR’s development of tools designed to meet the challenges of intelligent machining in the metalworking industry.

ISCAR aims to produce cutting tools that not only enhance metal removal rates but also offer repeatability, versatility, user-friendliness, and durability. These qualities represent the “IQ” of the tools, maximizing the potential of modern machine tools. This vision guides ISCAR’s development of tools designed to meet the challenges of intelligent machining in the metalworking industry.

The LOGIQUICK campaign introduces several groundbreaking cutting tools for turning, parting, grooving, hole-making, and milling. Key products in the lineup include innovations in rotating and non-rotating tools that address real-world machining challenges.

Rotating Tools for Enhanced Performance

One standout product is ISCAR’s new SUMOCHAM system, designed for drilling steel construction beams. These beams often require numerous holes, but issues with clamping rigidity can hinder performance. The SUMOCHAM concept offers an adaptive solution with interchangeable carbide drilling heads. The new PVD-coated IC954 carbide grade ensures resistance to deformation, while the reinforced drill body enhances rigidity, allowing effective drilling even under unstable conditions.

Additionally, ISCAR introduces the modular SUMOCHAM drill head with MULTI-MASTER adaptation. This versatile tool accommodates SUMOCHAM’s exchangeable heads, allowing easy customization in length, shape, and diameter. The combination of SUMOCHAM and MULTI-MASTER reduces the need for specialized drills and simplifies inventory management.

For efficient material removal in critical aerospace components made from titanium alloys, ISCAR unveils the QUICK-X-FLUTE milling cutter. This extended flute shell mill features double-sided inserts and an optimized flute design that strikes a balance between rigidity and chip flow, enabling higher metal removal rates. The high-pressure coolant system further enhances chip control and cooling.

Non-Rotating Tools for High-Temperature Superalloys

ISCAR also introduces IC1017, a new tungsten carbide grade designed for turning high-temperature superalloys (HTSA). This PVD-coated grade allows for higher cutting speeds, boosting productivity while maintaining surface quality. The LOGIQ-6-TURN triangular insert offers a cost-effective solution for semi-finishing and finishing, providing six indexable cutting edges compared to traditional two-edged inserts, improving tool life and cost efficiency.

Additionally, the DO-GRIP parting and grooving family has expanded with new double-sided inserts for narrow parting operations, specifically targeting Swiss-type lathes. These inserts maximize material savings when parting small-diameter bars and thin-walled workpieces.

ISCAR’s LOGIQUICK campaign represents a major step forward in metal cutting. The tools introduced promise to increase productivity, reduce costs, and enhance profitability for manufacturers. As the demand for faster and more efficient machining grows, ISCAR continues to lead the way with intelligent, innovative solutions that help manufacturers stay competitive.