Machining electronic components presents unique challenges due to the precise requirements and advanced materials involved. As technology advances, overcoming these challenges becomes increasingly critical to ensure the production of reliable and high-performance components. Addressing issues such as precision, contamination control, and material handling is essential for maintaining quality and efficiency in electronic component machining.

Achieving Extreme Precision

One of the foremost challenges in machining electronic components is achieving the extreme precision required for modern devices. Components are shrinking, with tolerances often reaching micrometers or even nanometers. Traditional machining methods may struggle to meet these stringent requirements, necessitating the adoption of advanced techniques. Innovations such as ultra-precision grinding, laser ablation, and micro-milling have emerged to address this need. These methods offer enhanced control over dimensions and surface finishes, enabling manufacturers to meet exacting standards.

Minimizing Contamination

Contamination is a critical concern in the machining of electronic components, as even minute particles can affect performance and reliability. Maintaining a clean environment throughout the machining process is essential. Implementing rigorous cleanliness protocols, including air filtration systems, cleanroom environments, and regular equipment maintenance, helps mitigate contamination risks. Additionally, using advanced coatings and lubricants designed to reduce particle generation can further minimize contamination and ensure component integrity.

Managing Advanced Materials

The use of advanced materials, such as high-performance ceramics and composites, presents additional challenges. These materials often require specialized machining techniques due to their unique properties, such as hardness or brittleness. Employing cutting tools made from materials like diamond or cubic boron nitride can enhance the ability to machine these materials effectively. Additionally, adjusting machining parameters, such as speed and feed rates, is crucial to accommodate the specific characteristics of advanced materials and achieve optimal results.

Enhancing Process Control and Automation

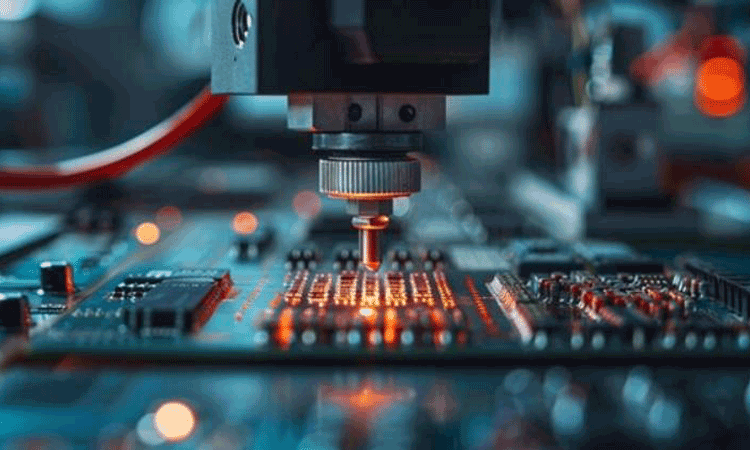

To overcome challenges associated with precision and efficiency, integrating smart technologies into machining processes is becoming increasingly important. Automated systems equipped with real-time monitoring, adaptive control, and predictive maintenance capabilities can significantly enhance process control. These technologies enable continuous adjustment of machining parameters, minimize human error, and ensure consistent quality throughout production. Advanced data analytics and machine learning can further optimize machining processes by identifying patterns and predicting potential issues before they arise.

Meeting Industry Standards

Compliance with industry standards and regulations is essential for ensuring the quality and reliability of electronic components. Adhering to standards such as ISO 9001 for quality management and ISO/IEC 17025 for testing and calibration ensures that machining processes meet required specifications. Regular audits and certifications help maintain high standards and address any deviations from established protocols.

Overcoming the challenges in machining electronic components requires a multifaceted approach involving advanced technologies, stringent cleanliness protocols, and adherence to industry standards. By focusing on precision, contamination control, material management, and process automation, manufacturers can enhance their machining capabilities and produce high-quality electronic components that meet the demands of today’s advanced technologies. As the industry continues to evolve, ongoing innovation and adaptation will be key to addressing emerging challenges and maintaining competitive advantage.