In the world of medical implant manufacturing, precision doesn’t stop at the CNC machine. The final stages — packaging, sterilization, and traceability — are just as critical as the machining itself. These downstream processes ensure that implants arrive in operating rooms not only in perfect mechanical condition but also safe, sterile, and fully traceable, in compliance with stringent regulatory standards.

As the industry grows more patient-specific and globally connected, manufacturers are realizing that the value of a finished implant lies equally in how it is packaged, labeled, and tracked. These steps are not afterthoughts; they are vital components of the medical manufacturing ecosystem.

The Importance of Sterile Packaging

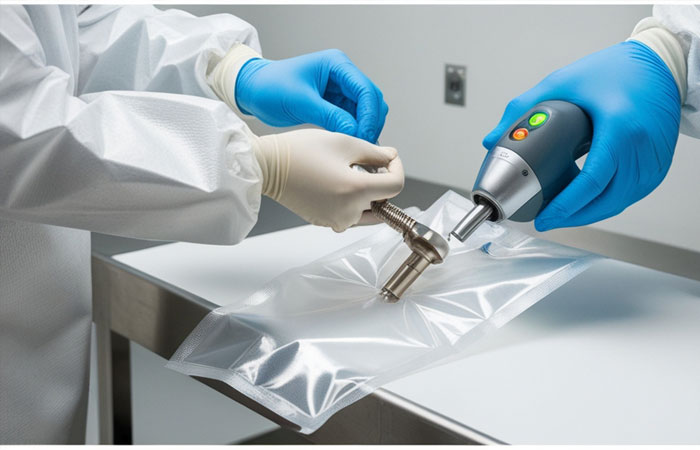

Once a medical implant is machined, cleaned, and finished, it must be protected from contamination during storage and transport. This is where medical-grade packaging plays a crucial role. Common solutions include double-barrier pouches, thermoformed trays, and Tyvek-sealed blisters, all designed to maintain sterility while withstanding shipping and handling.

The packaging material must be biocompatible and sterilizable, compatible with methods such as ethylene oxide (EtO), gamma irradiation, or autoclaving. Packaging is typically validated through tests like burst, seal, and microbial barrier integrity testing, as required by ISO 11607.

Furthermore, implants often need to be packaged in cleanroom environments (ISO Class 7 or 8) to prevent any microbial or particulate contamination. Many job shops now integrate clean packing zones alongside their machining and inspection departments.

Sterilization: The Final Gatekeeper

Sterilization is not just a technical step; it is a regulatory requirement. Depending on the material and intended use, manufacturers choose between various sterilization methods. For example:

- EtO is preferred for heat-sensitive materials like PEEK.

- Gamma radiation is widely used for titanium implants.

- Steam autoclaving is used for reusable surgical tools.

Sterilization processes must be validated per ISO 11135 (EtO) or ISO 11137 (radiation), ensuring consistent microbial reduction without damaging the implant.

Often, sterilization is outsourced to certified facilities, but coordination with machining and packaging teams is essential to ensure proper labeling, handling, and documentation.

Traceability: Connecting the Dots

Every medical implant must be fully traceable from raw material to final packaging. This is crucial not only for regulatory audits (FDA, CE, ISO 13485) but also for patient safety in case of recalls or adverse events.

Today, most implants feature laser-etched barcodes, QR codes, or unique device identifiers (UDI). These identifiers are linked to digital records that include material certificates, process steps, machine data, operator logs, and sterilization records.

Advanced ERP systems and Manufacturing Execution Systems (MES) enable seamless traceability across all departments — from the CNC machine to the packaging station. This level of transparency builds trust with hospitals, surgeons, and regulatory bodies.

Machining medical implants to perfection is only half the job. Ensuring they are packaged safely, sterilized reliably, and traceable completely is what brings them from the factory floor to the operating theatre with confidence. For manufacturers aiming to compete globally, these “beyond machining” processes are not just box-ticking exercises — they are the true finishing touches that uphold the integrity of modern medical care.