At the turn of the century, ISCAR transformed the world of holemaking with the introduction of assembled drills featuring exchangeable solid carbide cutting heads. These revolutionary tools marked a new era in drilling technology, eliminating the need for mechanical clamping and instead relying on the “self-clamping” principle — a concept now central to ISCAR’s highly successful SELF-GRIP and MULTI-MASTER product lines.

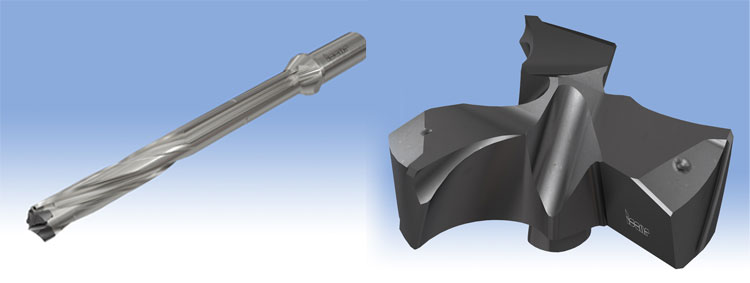

Each drill in this design features a precision-engineered carbide cutting head that integrates specialized rake surfaces for chip control, a centering zone for accuracy, and robust stoppers for secure mounting. Paired with a high-strength steel holder, complete with helical flutes and internal coolant channels, these tools exemplify cutting-edge engineering made possible by advancements in CNC machining and powder metallurgy.

The benefits of this design are significant. The rigid structure and innovative geometry ensure shorter cycle times, high-quality holes, and compatibility across various materials — from steel and stainless steel to titanium and high-temperature alloys. ISCAR’s “no-setup-time” approach enables users to replace worn heads without removing the drill from the machine, drastically reducing downtime. This user-friendly modularity also minimizes tool inventory by allowing the use of a single holder with multiple heads.

Over the past 20 years, this concept has evolved remarkably. Beginning with the CHAMDRILL family, ISCAR has consistently upgraded its lineup, culminating in the SUMOCHAM — its most popular exchangeable-head drill.

The latest innovation in this journey is the LOGIQ-3-CHAM, featuring three-flute drills for increased chip evacuation efficiency, especially when working with fine-chip-producing materials.

Taking this a step further, ISCAR’s LOGIQUICK campaign introduces groundbreaking enhancements. A new three-flute holder supports a 10:1 drilling depth-to-diameter ratio thanks to a specially designed flute geometry that maximizes strength. Additionally, the LOGIQ-3-CHAM now supports counterboring operations using custom heads that deliver improved chip control, enhanced guidance, and precise corner chamfers — ideal for tough materials like sticky steels and high-temperature superalloys.

Another standout is the CHAM-SPADE-IQ family, purpose-built for drilling steel construction beams under non-rigid conditions. These tools include two-flute carbide heads with self-centering edges and reinforced steel holders, ensuring dynamic stability and secure drilling in challenging applications.

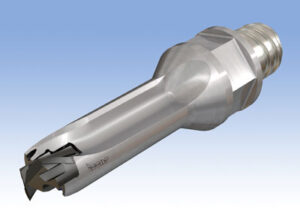

Bridging ISCAR’s leading technologies, the latest MULTI-MASTER-compatible drills incorporate exchangeable carbide heads into modular assemblies. This allows users to customize length, diameter, and tool configuration with ease — extending the capabilities of both the SUMOCHAM and MULTI-MASTER lines.

Beyond modular tools, LOGIQUICK innovations include a solid carbide three-flute flat-bottom drill with internal coolant, optimized for tool life and chip evacuation. Additional developments include digitally adjustable boring heads and the QUICK-D-MILL, a versatile indexable cutter for milling and flat-bottom drilling.

ISCAR’s relentless pursuit of drilling excellence continues to reshape holemaking technology. Through its LOGIQUICK campaign, the company delivers innovative, efficient, and highly adaptable solutions to meet the evolving demands of the global metalworking industry.