Precise material handling is not an option but a prerequisite in today’s complex industrial environment. Imagine a manufacturing plant where each article, be it delicate electronic goods or machine parts, needs to be handled with precision and caution. Every minor error can result in scheduling production, affecting the quality of the product, or even harming worker safety.

Precise material handling is not an option but a prerequisite in today’s complex industrial environment. Imagine a manufacturing plant where each article, be it delicate electronic goods or machine parts, needs to be handled with precision and caution. Every minor error can result in scheduling production, affecting the quality of the product, or even harming worker safety.

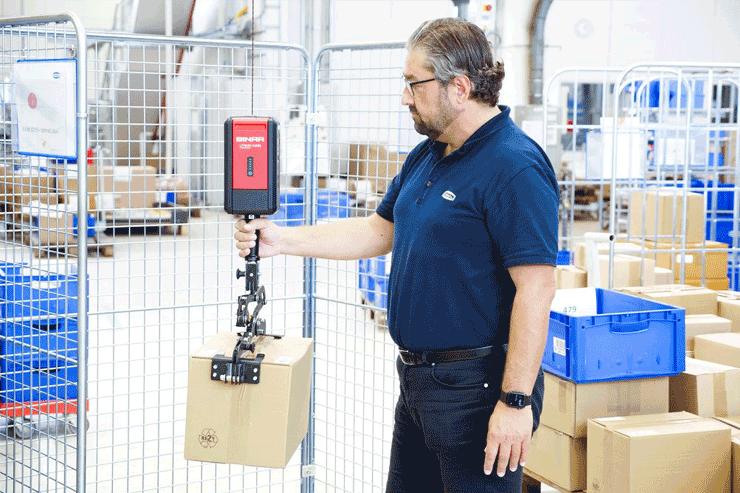

Make way for the Binar Rope Balancer NEO 30, taking Industrial Handling into another dimension. This sophisticated solution is tailored to meet the demanding requirements of modern production and logistics. The NEO 30 handles loads up to 30 kg without straining to ensure that small components move delicately but fast.

Innovative features for improved performance:

Battery operation and efficiency: NEO 30 features an enhanced front-integrated plug-in battery system that provides more mobility to operators by reducing the risk of entanglement from complex media connections. This ensures operators can move around more freely across workstations, which maximizes flexibility and operational output. NEO 30 achieves up to 500 lifting strokes per battery charge and hence offers prolonged uptimes with reduced disruptions, securing workflow continuity.

Versatile end effector compatibility: The Rope Balancer NEO 30 allows easy configurations with various end effectors like scissor grippers. It’s an Easy to use in common rail systems thanks to the swivel joint, which is attached to the trolley or an eyebolt. This means that the operator can now manipulate all types of boxes, paving stones, and industrial parts—with high precision and ease. The Rope Balancer NEO 30 fit for all kinds of material handling due to the possibility of easy integration of different tools into operation.

Ease of use in design: The NEO 30 has ergonomically been designed with operator comfort and intuitive control by its backlit on/off button and LED charge level indicator on the battery pack. Those very user-oriented features ease up the process of operation and monitoring, cutting down on errors and making for smooth handling in fast-moving industrial surroundings.

Durable and ergonomic build: NEO 30’s strong, rubberized body design adds to its durability in terms of constant use in industries. Its overall design is ergonomic, providing comfort for the operator during long-hour operations. The handle has smooth movement of control handles to it, making it easy to maneuver.

Applications and special usage

Ideal for sensitive and precise lifting operations: With ultimate control of handling tasks that require sensitivity and accuracy, the Binar Rope Balancer NEO 30 is inclusive. Its design allows intuitive control through sensory detection of manual force applied to the control handle, thus permitting operators to manipulate loads with precision directly on the workpiece. It has an electromotive rope mechanism that smoothly lifts by winding and unwinding the rope as necessary.

- Industry benefits: Binar Rope Balancer NEO 30 is designed to grant the following benefits to various industries:

- Exact handling: Precise and controlled handling for offering minimal risk of damage and improving the quality of manufactured products during various operations in industry and logistics.

- Higher productivity: Decreases manual handling efforts and cycle times, allows operators to deal with value-added tasks, and raises overall productivity.

- Safety and ergonomics: Present a solution with the ruled implementation of ergonomically correct operators’ lifting practices that can help decrease the operator fatigue and lower the propensity for workplace injuries.

The Binar Rope Balancer NEO 30 by Schmalz gives a new dimension to handling technology: innovative functions combined with ergonomic design, oriented to the dynamic expectations of industry in the 21st century. NEO 30 gives companies a new degree of productivity and reliability, insider-oriented handling with precision and efficiency of operation.