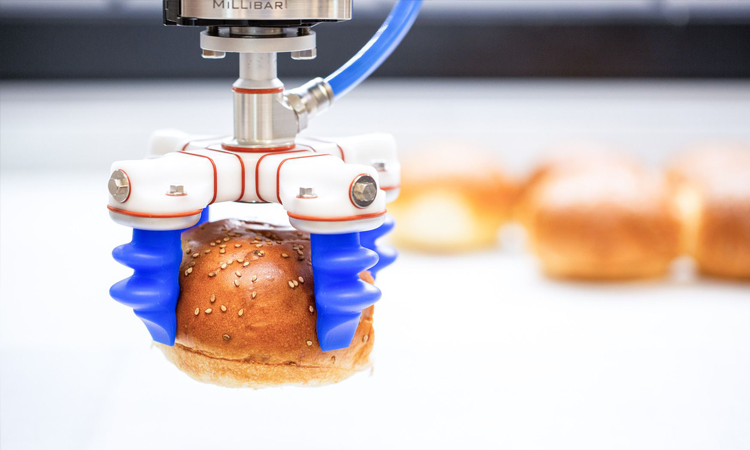

Schmalz, a leader in vacuum automation and ergonomic handling systems, has introduced the mGrip finger gripper, designed to meet the highest hygiene standards for handling sensitive products. The innovative design ensures gentle, precise handling of delicate items such as vegetables, baked goods, and other food products, offering food manufacturers a reliable solution to automate their processes with process safety and hygiene.

Schmalz, a leader in vacuum automation and ergonomic handling systems, has introduced the mGrip finger gripper, designed to meet the highest hygiene standards for handling sensitive products. The innovative design ensures gentle, precise handling of delicate items such as vegetables, baked goods, and other food products, offering food manufacturers a reliable solution to automate their processes with process safety and hygiene.

The mGrip gripper is engineered to handle a variety of shapes and sizes, including soft, fragile, spherical, and flat food products. Its unique finger design and modular structure allow for precise control, ensuring that even the most delicate food items are handled without damage. Whether it’s picking up baked goods or fruits, or even non-food items like bags or nets filled with small parts, the mGrip offers reliable and gentle automation solutions. With various configurations available, the gripper can be adapted to handle different products efficiently, ensuring that food manufacturers can achieve maximum productivity and hygienic standards.

A key feature of the mGrip is its hygienic design. Unlike mechanical systems, the pneumatically controlled mGrip offers highly sensitive handling, minimizing damage to delicate products while maintaining the required hygiene levels. Its closed system eliminates contamination risks, meeting the stringent requirements of Cleaning in Place (CIP) and Cleaning out of Place (COP) procedures. The gripper’s simple, lightweight structure makes it ideal for use with collaborative robots (cobots) and other lightweight robotic arms, further enhancing its suitability for high-speed automation tasks.

The mGrip offers excellent process stability, ensuring consistent and reliable handling in various industrial applications. Its modular design features adjustable finger sizes, opening angles, gripping forces, and positions, giving businesses the flexibility to customize the gripper for different tasks. This adaptability makes the mGrip an ideal solution for companies handling food products in high-speed production environments, as it allows for faster automation while minimizing the need for manual labor. By automating repetitive and labor-intensive tasks, companies can improve operational efficiency, reduce costs, and increase overall product quality.

Schmalz’s mGrip finger gripper represents a significant step forward in hygienic automation technology. With its focus on process reliability, hygiene, and flexibility, it provides an efficient solution for industries that require gentle handling of sensitive products, especially in high-speed applications. The gripper not only improves the handling of food items but also helps companies enhance their production processes by automating monotonous tasks, saving on labor costs, and ensuring higher hygiene standards.

Schmalz’s mGrip finger gripper is setting new standards for hygienic, efficient, and reliable automation in food processing and other industries. Its flexibility, process stability, and ability to handle delicate products make it a valuable asset for companies looking to enhance their productivity while ensuring the highest levels of hygiene and product quality.

For more information about the mGrip finger gripper, visit Schmalz’s website or contact their marketing department : Schmalz India Private Limited Visit www.schmalz.com