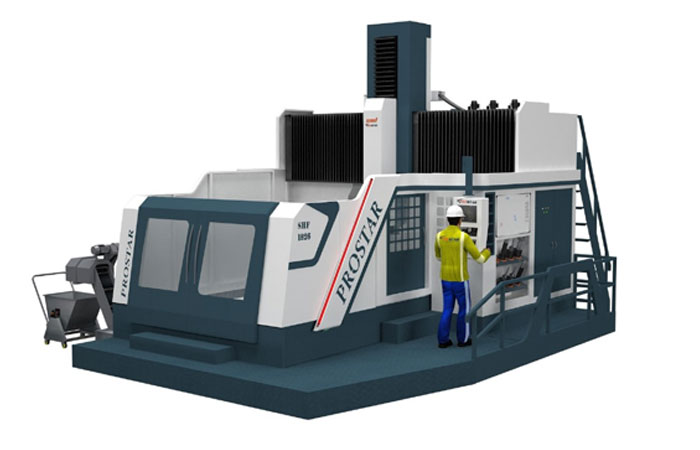

Shubhline Automation Pvt Ltd’s double column machining center is a state-of-the-art machine designed to meet the demands of precision machining and heavy-duty operations. This advanced equipment is particularly advantageous in the die and mold sector, where it excels due to its robust construction and ability to handle large and intricate workpieces with exceptional accuracy. Below is a detailed look at its features and applications within this industry.

Features of Shubhline Automation Pvt Ltd’s Double Column Machining Center

- Rigid Structure:

The double column design offers unparalleled rigidity and stability, crucial for precision during heavy-duty machining tasks.A wide base and sturdy columns minimize vibrations, ensuring consistent machining quality.

- High Precision:

Advanced control systems and high-quality linear guides deliver superior accuracy and repeatability.Precision ball screws and advanced servo motors enhance positioning accuracy.

- Large Work Area:

The spacious worktable can accommodate large molds and dies, ideal for manufacturing sizable components.Extended Y-axis travel facilitates the machining of taller workpieces.

- Versatility:

Supports various machining operations, including milling, drilling, and tapping, making it highly versatile.Compatible with different tooling systems to meet diverse machining requirements.

- Advanced Technology:

Incorporates cutting-edge CNC technology for optimal performance and user-friendliness.Features such as automatic tool changers, coolant systems, and chip conveyors boost productivity and efficiency.Applications in the Die and Mold Sector

- Mold Base Machining:

Ideal for machining mold bases, requiring high precision and excellent surface finish.Handles heavy and bulky mold bases efficiently due to its robust structure and large work area.

- Core and Cavity Machining:

Essential for creating intricate details in the core and cavity sections of molds.High precision ensures complex geometries and fine features are accurately machined.

- Electrode Machining:

Used in EDM (Electrical Discharge Machining) for creating electrodes critical for mold making.Provides the accuracy and finish needed for high-quality electrode production.

- Die Machining:

Suitable for machining various types of dies, including stamping, extrusion, and forging dies.Capable of handling large and heavy workpieces, making it ideal for die manufacturing.

- Prototype and Tooling:

Useful for producing prototype molds and tooling, allowing for design testing and refinement before full-scale production.Ensures prototypes meet stringent quality and dimensional requirements.

Benefits to the Die and Mold Sector

- Increased Efficiency:

The robust design and advanced features reduce machining time and increase throughput. - Enhanced Quality:

High precision and stability ensure superior quality and finish, resulting in better-performing molds and dies. - Cost-Effective:

Reduces the need for multiple setups and operations, lowering production costs and improving profitability. - Versatility:

Capable of handling a wide range of machining tasks, making it a valuable asset for mold and die manufacturers.

Shubhline Automation Pvt Ltd’s double column machining center offers numerous advantages to the die and mold sector, including improved precision, efficiency, and versatility. Its robust construction and advanced technology make it an indispensable tool for manufacturers aiming to produce high-quality molds and dies.

For more information and to see how Shubhline Automation’s double column machining center can revolutionize your die and mold manufacturing process, contact us today! Visit: ┬Āwww.shubhlinegroup.co.in