Polycrystalline Cubic Boron Nitride (PCBN) tooling is transforming the automotive machining industry with its exceptional capabilities in high-speed machining and precision cutting. As a synthetic material, PCBN is extremely hard and offers excellent thermal stability, making it ideal for working with ferrous materials like hardened steels, cast irons, and superalloys.

Several trends are shaping the global PCBN tooling market. The automotive sector, among others, is increasingly relying on PCBN tools for their superior cutting performance. Manufacturers are heavily investing in R&D to enhance the durability and efficiency of these tools. There’s also a noticeable shift towards customizing PCBN tools to meet specific needs. Moreover, integrating PCBN tooling with artificial intelligence and industrial automation is expected to redefine the future of this market.

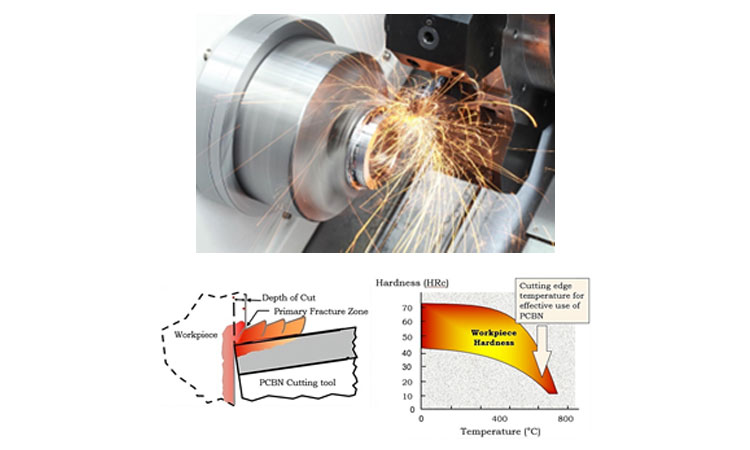

PCBN’s effectiveness in machining hardened steel components, typically in the 45 to 70 HRC range, stems from its ability to generate high temperatures (700-800°C) in the cutting zone. This heat softens the workpiece material, allowing for easier cutting and extended tool life. When machining grey cast iron, which is softer but more abrasive, PCBN still excels due to its durability, though heat generation is less critical compared to harder materials.

A crucial factor in maximizing PCBN tool life is proper edge preparation of the inserts. Techniques vary from a small hone for finishing to a T-land for heavy roughing, with combined lands and hones also used to enhance performance.

Looking ahead, the PCBN tooling market holds promising potential. The automotive industry’s demand for high-speed, precision cutting tools is growing, driven by PCBN’s advantages over conventional materials, including longer tool life, higher cutting speeds, and better surface finishes. Innovations such as micro-structured PCBN tools are further boosting market growth by enabling higher material removal rates and improved chip control, leading to increased productivity and lower machining costs.

For more information on how PCBN tooling can enhance your automotive machining processes, contact at rajesh@rudrali.com